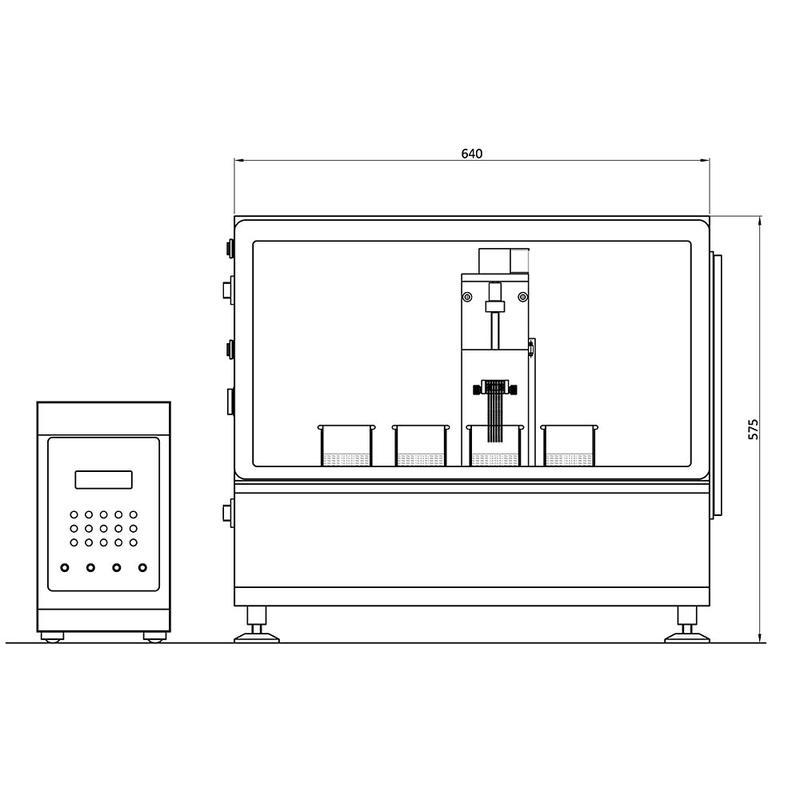

PTL-SC-4S-LD features an air-tight chamber with a front observation window. The unit provides inlet and outlet valves for inert gas purging. This helps to protect samples from moisture or oxygen exposure at the end of the coating process. It provides four separate platforms to place coating solutions each with magnetic stirrer. User can also control the speed of the magnetic stirrer for each beaker independently by using the knobs on the front panel of the controller.

In this technique, the thin film is deposited on glass substrate following a chemical technique called successive ion layer adsorption and reaction (SILAR). The technique involves multiple dipping of the substrate in a given solution and deionized water, the temperature of both can vary from case to case.

SPECIFICATIONS:

|

Power Input

|

208-240VAC, 50/ 60Hz

|

|

Air Tight Chamber

|

-

Provision of inlet and outlet valves for gas purging

-

Chamber size: 640L x 475W x 575H mm

-

|

|

Actuator

|

Stepper motor

|

|

Drive Mechanism

|

Lead screw

|

|

Dip Duration

|

0 - 99 seconds / minutes / hours

|

|

Speed Control

|

Drawing speed adjustable from a digital panel from 2 microns/sec to 9000 micron/sec ( Max.)

|

|

Number of Dips

|

1 - 999

|

|

Stirrer Speed

|

-

0 - 999 rpm

-

Independent speed control over 4 working positions

|

|

Stroke length Max.

|

100 mm

|

|

Control Unit

|

Speed and mode control via LED display

|

|

Compliance

|

-

TUV(UL61010) or CSA certification is available at extra cost. please click marks below to learn details )

|

|

Application note

|

-

In order to get better film coating, the substrate shall be treated by plasma cleaner (Please click on the first picture below for more information)

-

Use ultrasonic processor to disperse nano powder or homogenize solution to get better coating (Please click on the second picture below for more information)

|

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported