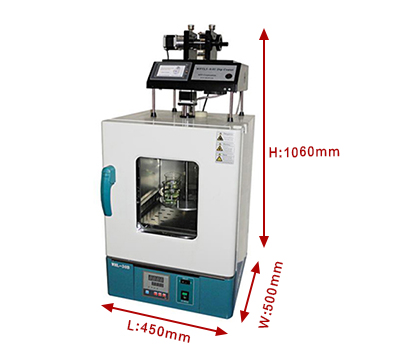

Lab Automatic Five Stations Thermostatic Lift and Pull Film Coater

Description:

PTL-OV5P automatic 5-station thermostatic lift and pull film coater is used for multi-layer impregnation and coating of the same part in different liquid phases, up to 5 layers. The machine is equipped with a lifting wire that can hold up to two identical samples at the same time for impregnation and coating, and the PTL-OV5P automatic 5-station thermostatic lifting and coating machine can set the lifting speed, falling speed and impregnation time of the sample in the liquid phase film material during the working process. After completing the impregnation and coating in the liquid phase once, the loading cup is automatically transferred to the next process. The machine is equipped with a thermostatic drying oven, so that the film growth process is carried out at a constant temperature and is conducive to film curing. PTL-OV5P automatic 5-station thermostatic lift and pull film coater can save laboratory space cause its compact size; it is suitable for beginners for its easy operation and easy to clean up. Therefore, this machine is widely used in the field of nano, chemical, metal and other materials, moreover, it is the ideal equipment for film coating in the majority of higher education institutions and research institutes. (Customized micron and nano-level lifters for this product are available)

Main features:

1. Using touch control screen, set the lifting speed, falling speed and dwell time according to actual needs.

2. The whole process of dipping and pulling coating is carried out in a constant temperature field, which is conducive to film formation and curing.

3. After completing one kind of liquid phase coating, it automatically moves to the next process.

4. Adopt the technology of overhanging motor for vibration reduction.

5. Adopt high precision stepping motor.

6. 5-station liquid phase carrier plate rotates automatically according to the program.

7. It has passed CE certification.

Technical Parameters:

Product Name

PTL-OV5P automatic 5-station thermostatic lift and pull film coater

Model Number

PTL-OV5P

Mounting Conditions

This equipment is required to be used under 1000m above sea level, 25℃±15℃ and 55%Rh±10%Rh humidity.

1. Water: without

1. Electricity: AC220V 50Hz, must be well grounded

2. Gas: without

3. Working station: size 800mm × 600mm × 700mm, load capacity of 200kg or more

4. Ventilation device: without

Main Parameters

1. External power supply of the host: AC220V, 50Hz, 3A, 850W

2. Lifting speed: 1mm/min-200mm/min

3. Temperature:RT-100℃

4. Load cup: Φ60mm, 150ml

5. Dipping and drying time setting:1-999s

6. The number of times each of the five stations can be lifted: 1-20 times

7. Effective impregnation length:60mm

8. Sample size: 75mm×25 mm×2.5mm

9. Ambient temperature: 5~40℃, relative humidity not more than 85%RH, no strong shock source and corrosive gas around the equipment.

10. Constant temperature box technical parameters.

11. Temperature range: room temperature +5~100℃

12. Temperature fluctuation: ±1.5℃

13. Outline size: 460×510×695

Product Specification

Size: 450mm x 500mm x 1060mm.

Weight: 45kg

Standard Accessories

1. 1 set of coating fixture

2. Carrier cup (150ml) 5 pcs

3. Lifting wire 3 pcs

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported