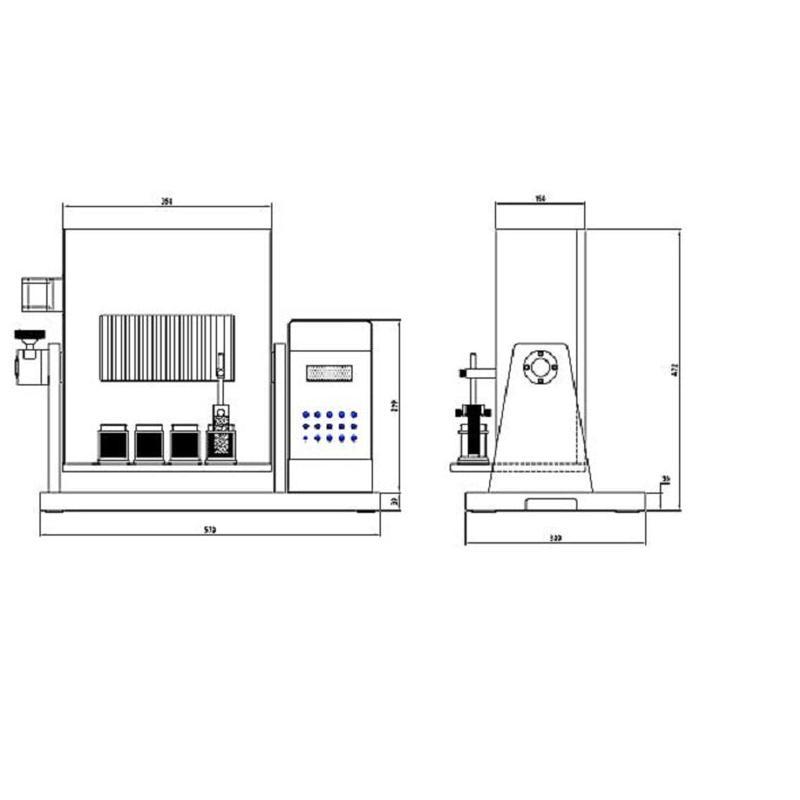

6 Position 350C SILAR Coating System Independent Controlled Stirrer & Heater

PTL-SC-6S-LD Coating System has been designed to automate the entire process to avoid operator fatigue and errors associated with it. In the manual SILAR process, the operator has to perform hundreds of repetitive dipping into the solution and water. It is very difficult to control dip duration and number of dips in a manual process which can last hours. In the automated unit, the operator needs just to clamp the substrate into the holder and program the controller with required dip cycles and duration.

PTL-SC-6S-LD has a motorized substrate holder. The dipping speed, stirring speed, dip duration, retrieval speed, and dry duration can be set for each beaker. Six hot plates can be set at different temperatures independently up to 350°C from ambient.

In this technique, the thin film is deposited on a glass substrate following a chemical technique called successive ion layer adsorption and reaction (SILAR). The technique involves multiple dipping of the substrate in a given solution and deionized water, the temperature of both can vary from case to case.

Power Input

|

|

| Actuator | Stepper motor |

| Drive Mechanism | Lead screw |

| Dip Duration | 0 - 99 seconds / minutes / hours |

| Speed Control | Drawing speed adjustable from a digital panel from 2 microns/sec to 9000 micron/sec ( Max.) |

| Number of Dips | 1 - 999 |

| Hot Plate Temperature | Ambient to 350°C for each hot plate ( 6 in total ) |

| Beaker |

|

| Stirrer Speed | 1 - 200 rpm |

| Thermocouple | 6 K-type thermocouple built-in |

| Extension Sample Clip |

One extension sample clip can be used if you need to dip a small sample into the larger beaker. Size: supporting rod 10cm long; clipping head: 2cm long.

|

| Stroke length Max. | 75 mm |

|

Control Unit |

|

| Certificate | All electric components ( >24V) are UL certified. (except heating element) |

| Compliance |

|

| Application note |

|

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported