Multistation Dip Coating Machine For Metal process With Multi-Temperature for Thin Film Research

Product Overview

The TMAX-KJ06H six-station dip coater processes one sample at a time through programmable counterclockwise rotation. Samples are immersed in material-loaded beakers for preset durations before being lifted for drying, with both immersion and drying times being fully adjustable.

System Features

· Six independent workstations

· Counterclockwise sample rotation

· Programmable parameters (speed, time, temperature)

· Six individually controlled heating zones

· CE certified

· Space-saving compact design

· User-friendly operation suitable for beginners

· Easy maintenance and cleaning

Installation Conditions

The equipment must operate under the following conditions:

· Altitude: Below 1,000 m

· Temperature: 25°C ±15°C

· Humidity: 55%RH ±10%RH

Utility Requirements

|

Requirement |

Specification |

|

Water |

Not required |

|

Power |

AC 220V, 50Hz (with proper grounding) |

|

Gas |

Not required |

|

Workbench |

Dimensions: 500mm × 800mm × 700mm, bearing capacity ≥50kg |

|

Ventilation |

Not required |

Technical Parameters

|

Parameter |

Specification |

|

Power Supply |

220V, 1200W |

|

Stirring Speed |

1–5 rpm/s (configurable per station) |

|

Lifting Speed (Automatic) |

1–400 mm/min |

|

Lifting Speed (Manual) |

1–150 mm/min |

|

Lifting Cycles |

1–45 times |

|

Immersion & Drying Time Setting |

1–999s |

|

Stroke Setting |

1–80mm |

|

Material Beaker Capacity |

150ml |

|

Sample Dimensions |

75mm × 25mm × 2mm |

|

Effective Immersion Length |

60mm |

|

Heating Temperature |

RT–80°C (individually adjustable per station) |

Product Specifications

· Dimensions: 260mm × 340mm × 420mm

· Weight: 15kg

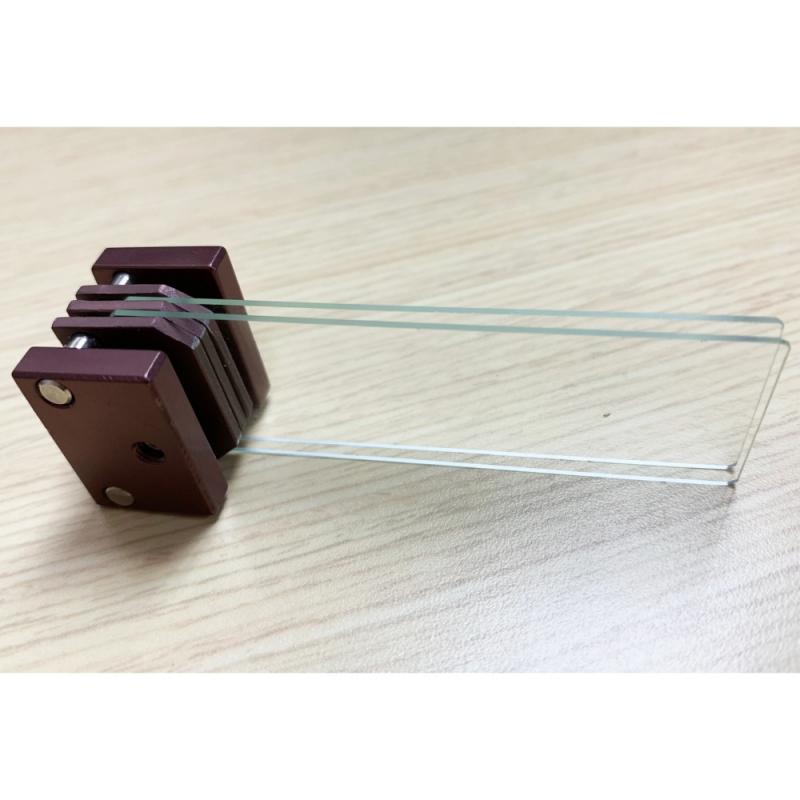

Standard Accessories

1. Single-sample holder ×1

2. Material beakers ×6

Optional Accessories

· Double-sample holder

· Other custom holders

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported