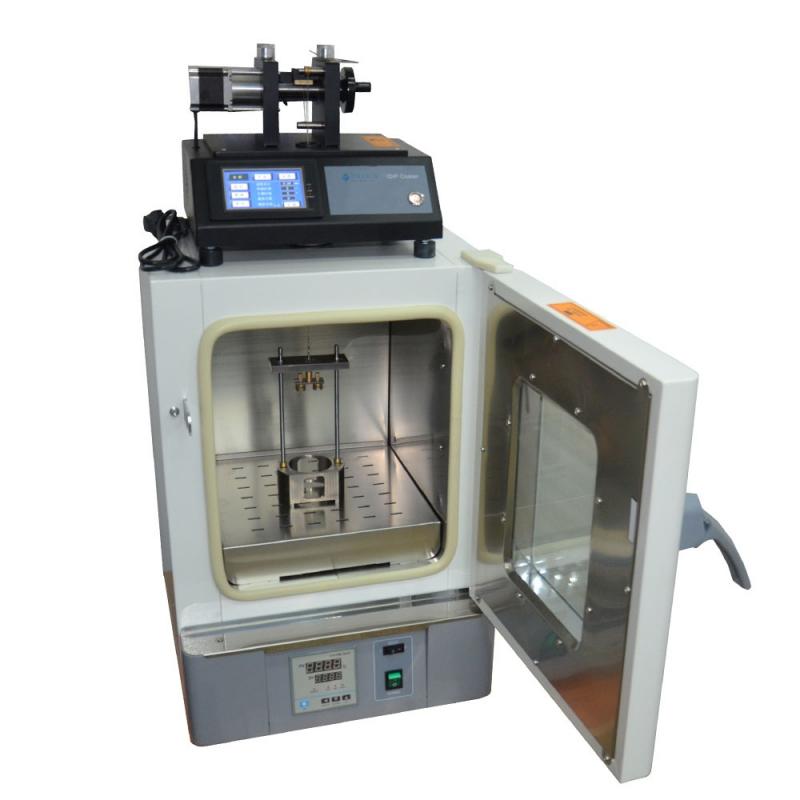

Heated Dip Coating Systems With 100C Constant Drying Oven And Touch Screen

The LITH-KJ012O Programmable Dip Coater is a CE-certified product designed for precise millimeter-level immersion and withdrawal coating experiments in liquid-phase film growth applications. This equipment is essential for research institutions engaged in liquid-phase thin film deposition.

Technical Specifications:

Control System:

· PLC-based programmable control system

· High-precision stepper motor with mechanical actuator and lifting wire for smooth and accurate vertical motion

Operation Modes:

· Single-cycle operation

· Full-cycle operation

Programmable Parameters:

· Withdrawal speed: 1–200 mm/min (±0.05% accuracy)

· Immersion speed: 1–200 mm/min (±0.05% accuracy)

· Dwell time in solution: Adjustable (max. 999 sec)

· Drying time: Adjustable

· Cycle repetition: Up to 20 times

Models Available:

· TMAX-KJ01B: Standard (room temperature)

· TMAX-KJ012O: With thermostatic drying oven (up to 100°C)

General Features:

· Compact design, user-friendly operation, and portability

· Widely used in universities, research institutes, and industrial laboratories

Detailed Specifications:

Electrical Parameters:

· Input Voltage: 110/220V AC (selectable)

Mechanical Parameters:

· Travel Distance: 0–60 mm (adjustable)

· Dipping/Pulling Speed: 1–200 mm/min (programmable, ±0.05% accuracy)

· Sample Holder:

o Equipped with two screw-clip fixtures

o Guided by dual vertical rods for stable movement

· Max. Sample Size: 3" (L) × 2" (W)

· Max. Sample Weight: ≤250g

Solution Handling:

· Included Container: 150 mL beaker

· Beaker Holder: Dedicated slot for secure placement

Drying Oven (TMAX-KJ012O Model):

· Max. Temperature: 100°C (±1°C accuracy)

· Heating Power: 600W

· Chamber Dimensions (Internal): 280 × 280 × 280 mm (L×W×H)

· Chamber Material: Stainless steel

· Overall Dimensions: 406 × 406 × 610 mm (L×W×H)

Certifications:

· CE Certified

· NRTL/CSA available upon request (additional cost)

Application Notes:

1. For optimal film uniformity, pre-treat substrates with a plasma cleaner.

2. For nanoparticle dispersion or solution homogenization, use an ultrasonic processor.

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported