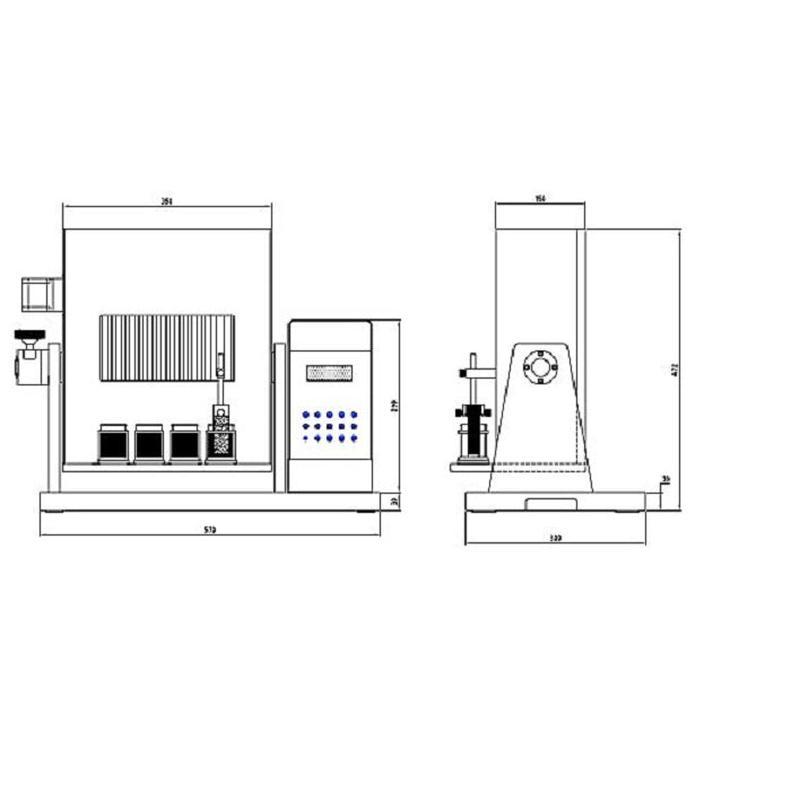

Digital Panel Adjustable Speed Dip Coater with Drying Oven up to 100C

PTL-AADC is an Angle Dependant Dip Coating unit, which enables nano layer coating of substrates by dipping them in beakers containing coating solution. The dipping angle can be varied from 0 to 45 degree depending upon the requirement. There are 4 beaker holders provided for coating 4 different substrates. The dipping speed, dip duration, withdrawal speed and dry duration can be varied for each beaker independently.

Basic principle of ADDC: The substrate is drawn out of the coating solution under a well defined angle of inclination. Both surfaces are coated simultaneously resulting in different film thickness on front and back side. One of the advantages of ADDC is the reduced number of layers or coating steps to obtain the desired thin film properties.

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported