Benchtop 4-Station Multi-Layer Heating Dip Coating Process Coater

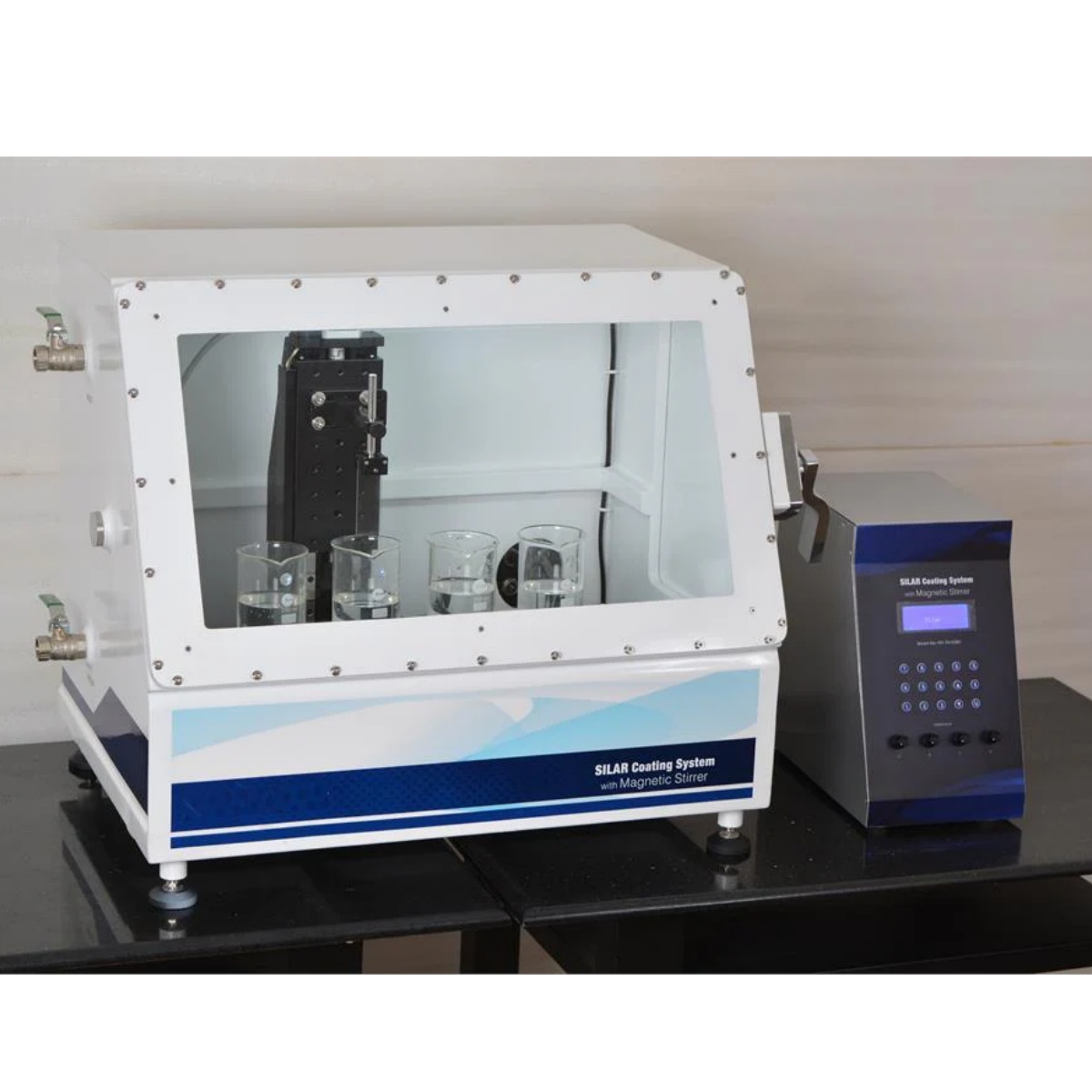

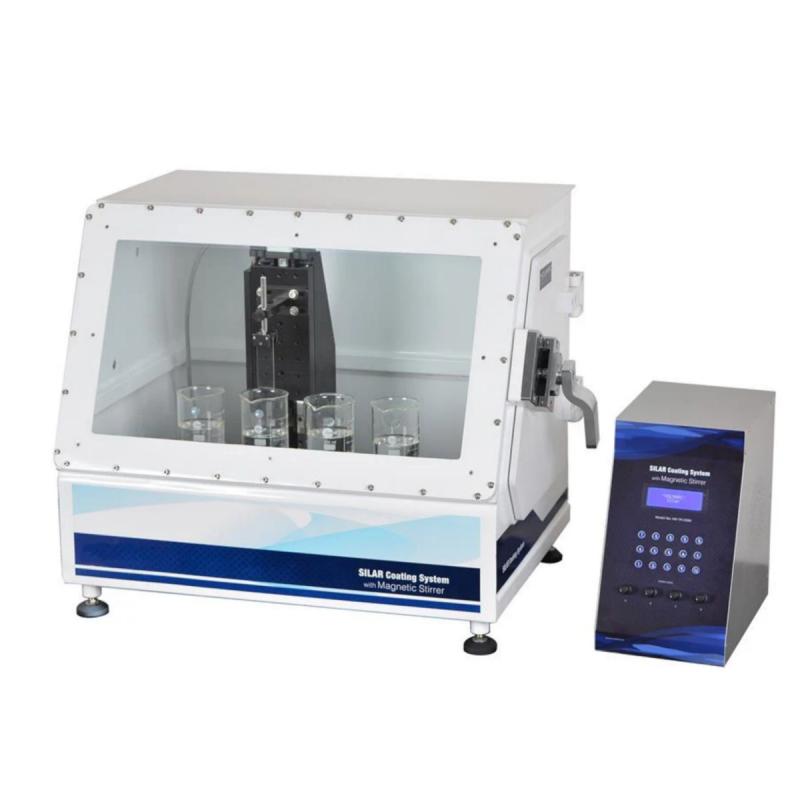

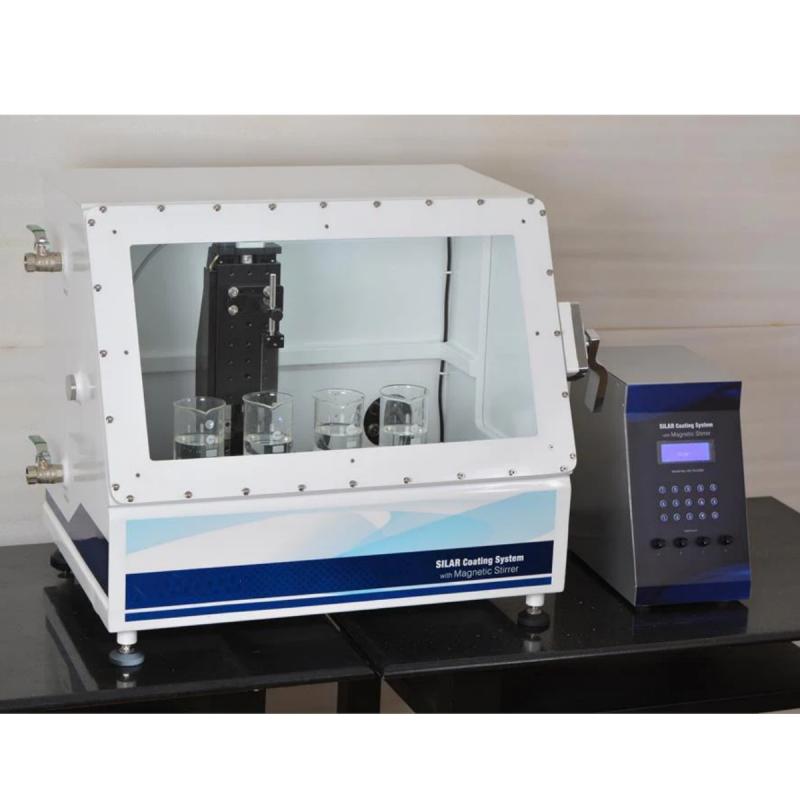

The LITH-04C features an air-tight chamber with a front observation window. The unit includes inlet and outlet valves for inert gas purging to protect samples from moisture or oxygen exposure post-coating. It provides four independent platforms for coating solutions, each equipped with a magnetic stirrer. Stirring speeds for individual beakers are adjustable via knobs on the front panel.

This system deposits thin films on substrates using the Successive Ionic Layer Adsorption and Reaction (SILAR) method, involving repeated immersion in solution and deionized water (temperatures adjustable per requirements).

SPECIFICATIONS

Power Input

· Voltage: 208–240 VAC

· Frequency: 50/60 Hz

Air-Tight Chamber

· Gas purging: Inlet/outlet valves

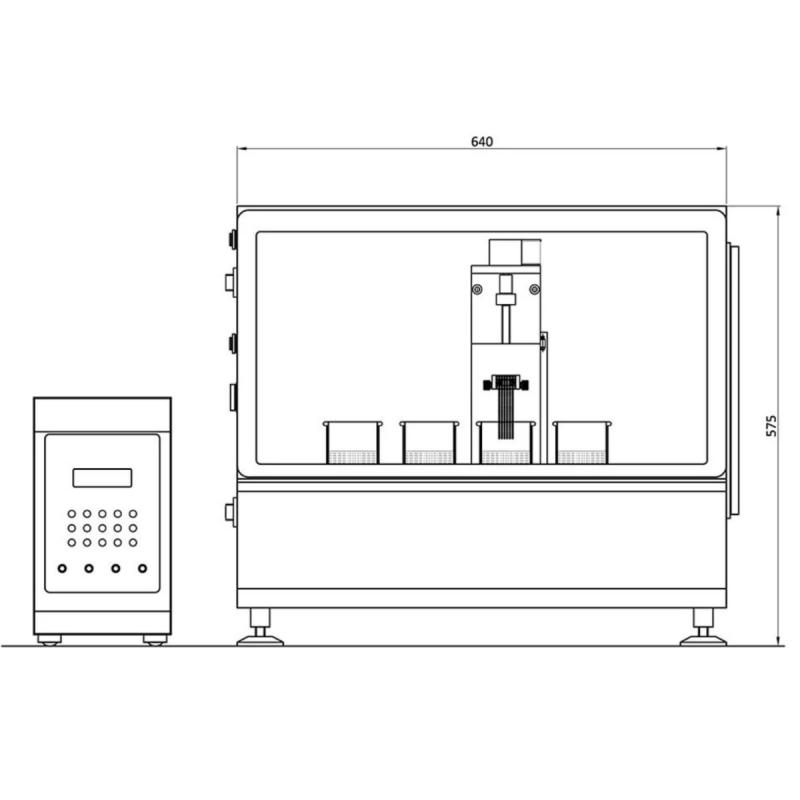

· Dimensions: 640 (L) × 475 (W) × 575 (H) mm

Actuator & Drive

· Actuator: Stepper motor

· Drive mechanism: Lead screw

Dip Parameters

· Dip duration: 0–99 sec/min/hr

· Drawing speed: 2–9,000 µm/sec (adjustable via digital panel)

· Max stroke length: 100 mm

· Number of dips: 1–999

Magnetic Stirrer

· Speed range: 0–999 rpm

· Control: Independent speed for all 4 positions

Control Unit

· Interface: LED display for speed/mode adjustment

Compliance

· TUV (UL61010) or CSA certification (available at extra cost)

Application Notes

1. Substrate pretreatment: Plasma cleaning recommended for optimal film quality.

2. Solution preparation: Use an ultrasonic processor to disperse nanopowders or homogenize solutions.

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported