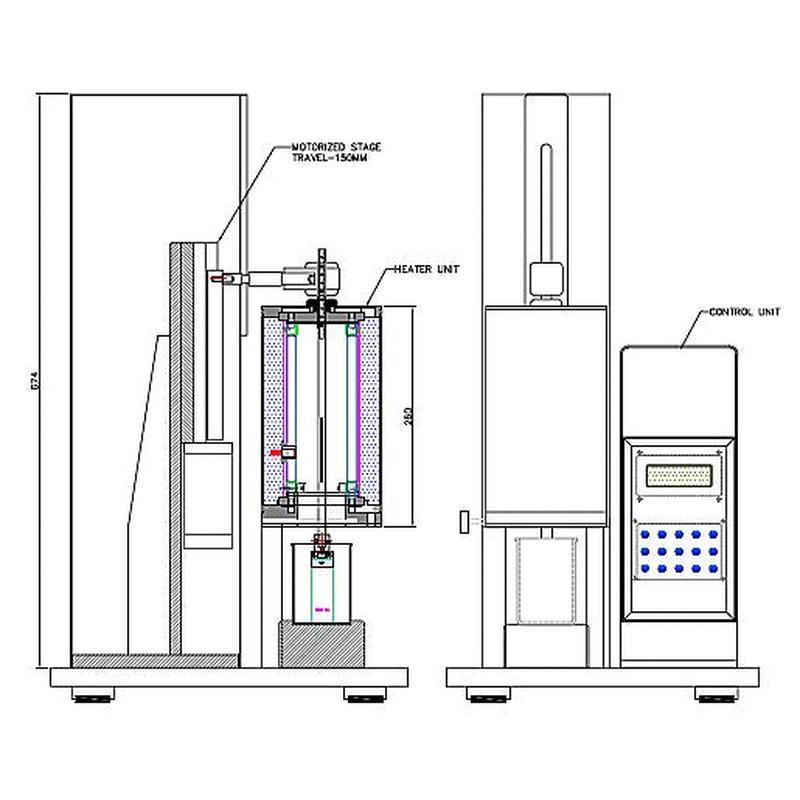

Five Programs Memory Table-Top Speed Adjustable Dip Coating Unit with Infrared Heater

The Dip coating unit with an infrared dryer (PTL-HT-2-LD) is designed to keep operator involvement as minimum as possible so that variables like speed, duration, etc. are maintained accurately by the microcontroller. Movements are achieved by a precision servo motor controlled linear stage that offers vibration and noise free operation. It helps to create a uniform coating on the substrate.

The dip coating unit with infrared dryer has both manual as well as PC mode. In manual mode, a user-friendly front panel with keyboard and LCD display is provided to enter all dipping and withdrawal parameters. As in PC mode, the entire unit can be controlled by user-friendly software. It is also possible to save programs for future use.

PTL-HT-2-LD Dip coating unit with infrared dryer has an infrared dryer incorporated with it, whose temperature can be set to a maximum of 200°C from ambient. This is meant for drying the substrate after the coating has been made. It has an infrared bulb inside.

Dip coating unit with infrared dryer is mainly used in physics, chemistry and biotechnology labs and corresponding research activities.

| Actuator | Servo motor |

| Drive mechanism | Lead screw |

| Speed control | Drawing speed adjustable from the digital panel from2 microns/sec to 9000 micron/sec (Max.) |

| Power Input |

|

| Stroke length max. | 150mm |

| Max Substrate size | 40mm x 50mm |

| Control Unit |

|

|

Substrate Holder |

|

| Certificate | CE Certified |

| Application notes |

|

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported