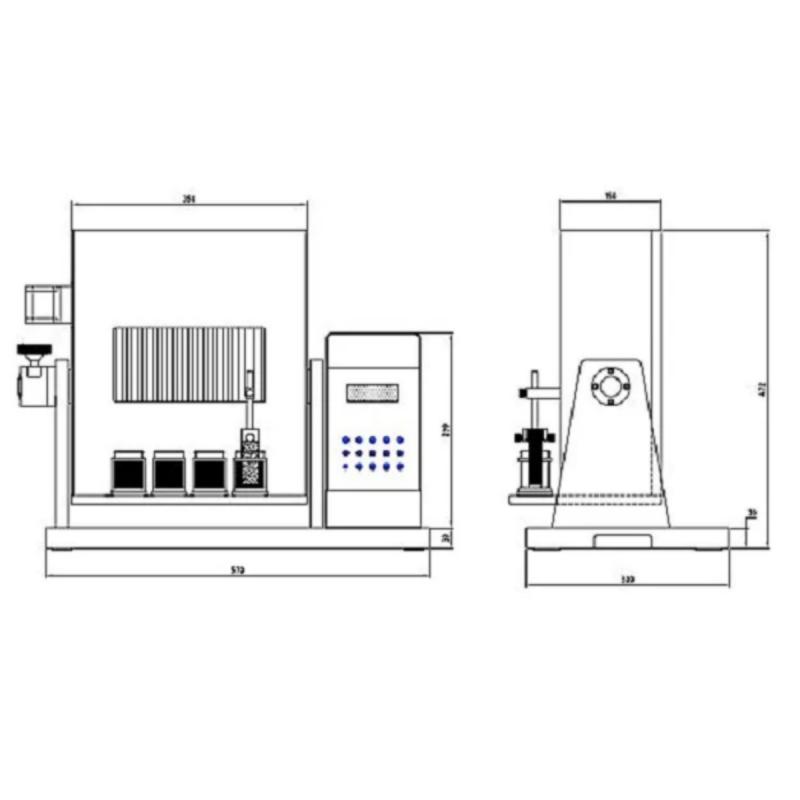

6-Position Programmable PLC Dip Coating System Coater With Stirrer & Heater For Metal Process

The Lith-06H Coating System automates the entire SILAR process to eliminate operator fatigue and manual errors. Unlike manual dipping—which requires hundreds of repetitions and struggles with timing control—this system only requires the operator to clamp the substrate, program dip cycles, and set durations.

Key Features

· Motorized substrate holder with adjustable dipping, stirring, and retrieval speeds.

· Six independent hot plates (up to 350°C each).

· Digital control for dip duration, dry time, stir speed, and temperature.

· Compatible with gloveboxes and fume hoods for controlled environments.

Specifications

|

Parameter |

Specification |

|

Power Input |

208–240 VAC, 50/60 Hz |

|

Max Power Consumption |

600 W (with heater) |

|

110V Operation |

Requires 750W transformer (click left image to order) |

|

Actuator |

Stepper motor |

|

Drive Mechanism |

Lead screw |

|

Dip Duration |

0–99 sec/min/h |

|

Speed Control |

2–9000 µm/sec (digital adjustment) |

|

Number of Dips |

1–999 cycles |

|

Hot Plate Temperature |

Ambient to 350°C (6 independent plates) |

|

Recommended Beaker |

100 mL (50 mm OD) – not included |

|

Stirrer Speed |

1–200 RPM |

|

Thermocouple |

6 × K-type (built-in) |

|

Extension Sample Clip |

10 cm rod + 2 cm head |

|

Max Stroke Length |

75 mm |

|

Control Interface |

LED display (5-program memory) |

|

Temp. Control Accuracy |

±1°C (up to 350°C) |

|

Certifications |

UL (components >24V, excluding heater), CE |

|

Optional Certifications |

NRTL/CSA (available upon request) |

Application Notes

✔ For optimal coating:

· Pre-treat substrates with a plasma cleaner.

· Use an ultrasonic processor for nanoparticle dispersion.

✔ Environment options:

· Can be operated inside a glovebox (controlled atmosphere).

· Place in a fume hood if liquids emit vapor

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported