Lab Vacuum Casting Coater Equipment with Vacuum Suction Cup

Product Name:Lab Casting and Coating Machine

MSK-AFA-L800 cast coating machine uses vacuum suction cup and oil-free vacuum pump to adsorb and fix the substrate, which makes the substrate wrinkle-free during the coating process, thus making the coating more uniform and smooth, and also prevents the pollution of the substrate by oil in the vacuum pump. The thickness of the film can be adjusted according to the micrometer above the squeegee. If the gap between the squeegee and the substrate is small, the film thickness will be thin; if the gap between the squeegee and the substrate is large, the film thickness will be thick. The film length can be up to 800mm with the micrometer adjustable film maker, and the unique auto-propulsion device can produce smooth coating on any material within the range of 250mm wide and 800mm long, which is an ideal tool for low cost R&D and production of 18650 lithium battery electrode material.

Features:

1. Using transverse push rod with micron level film maker.

2. Adjustable limit switch to control the coating stroke.

3. Adopt vacuum adsorption method to fix the substrate.

4. Adjustable coating speed.

5. It has passed CE certification.

Technical parameters:

|

Product Name |

MSK-AFA-L800 Casting and Coating Machine |

|

Model Number |

MSK-AFA-L800 |

|

Mounting Conditions |

This equipment is required to be used under 1000m above sea level, 25℃±15℃ and 55%Rh±10%Rh humidity. 1. Water: without 2. Electricity: AC220V 50Hz, must be well grounded 3. Gas: without 4. Working station: size 800mm × 600mm × 700mm, load capacity of 200kg or more 5. Ventilation device: without |

|

Main Parameters |

1. Power supply: 110V/220V 60Hz/50Hz 2. Total power: 150W 3. Coating speed: 10mm/s-100mm/s adjustable 4. Coating stroke: 10mm -800mm 5. Vacuum board size:800mm×260mm 6. Vacuumable size:740mm×218mm 7. Film maker: 180mm micron level adjustable (other sizes can be selected) adjustment range 0.01mm-5mm 8. Membrane thickness accuracy: ±0.01mm |

|

Product Specification |

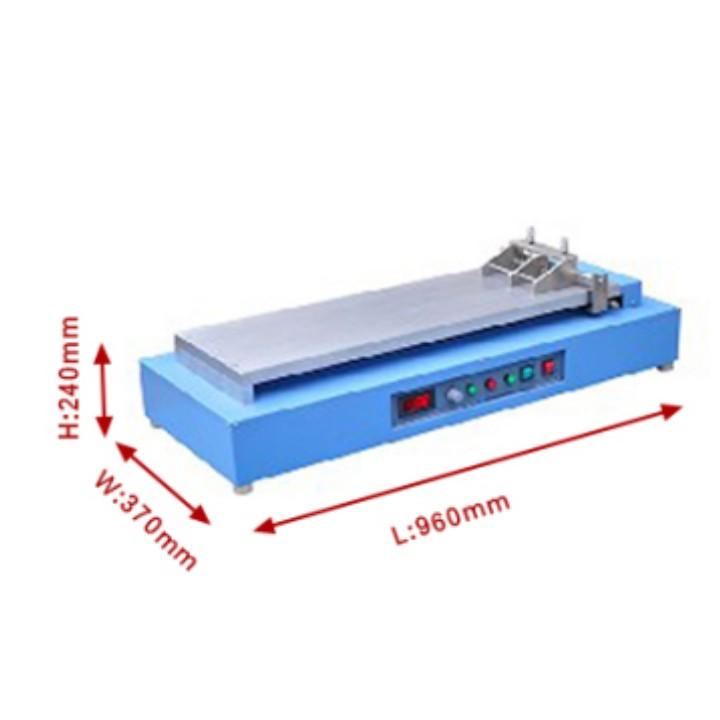

Dimensions: 960mm x 370mm x 240mm.

Weight: 50kg |

Standard Accessories:

|

No. |

Name |

Amount |

Picture |

|

1 |

Pusher bar |

1 |

|

|

2 |

Aggregate box |

1 |

|

|

3 |

150mm micrometer modifiable membranes |

1 |

|

|

4 |

Ingredient cup |

1 |

|

Optional Accessories:

|

No. |

Name |

Function Category |

Picture |

|

1 |

Vacuum pump (AP-1400V oil-free vacuum pump) |

(avaliable) |

|

|

2 |

Micrometer modifiable membrane-50mm |

(avaliable) |

|

|

3 |

Micrometer modifiable membrane-100mm |

(avaliable) |

|

|

4 |

Left and right modifiable membrane device - 150mm |

(avaliable) |

|

|

5 |

Double squeegee micrometer modifiable film holder - 150mm |

(avaliable) |

|

|

6 |

Top and bottom modifiable filmers-180mm |

(avaliable) |

|

|

7 |

Vacuum Mixer |

(avaliable) |

|

|

8 |

Viscometer |

(avaliable) |

|

|

9 |

Frame Preparer |

(avaliable) |

|

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported