Lab High Temperature Casting Coater Cast Coating Device

Product Name: Lab High Temperature Casting Coater

MSK-AFA-H300A is a high temperature cast coater with heated vacuum suction plate up to 300°C. This machine is specially designed for coating various high temperature polymer materials and also for preparing various ceramic films and battery electrode films.

Technical parameters:

|

Product Name |

MSK-AFA-H300A high temperature cast coater |

|

Model Number |

MSK-AFA-H300A |

|

Main Parameters |

Power requirements: Voltage: 208-240VAC 50/60Hz; Power: 1.2KW Coating area: standard coating area: 350mm (L) x 180mm (W); coating length: 10-350mm (adjustable by position adjustment knob) Coating thickness accuracy: +/- 0.01mm Pusher movement speed & stroke: movement speed: 0 - 80mm/s (adjustable); stroke: 0 - 400 mm (adjustable) Top heating cover (optional): optional top heating cover for heating up to 300ºC, temperature control accuracy: +/- 1.0ºC |

|

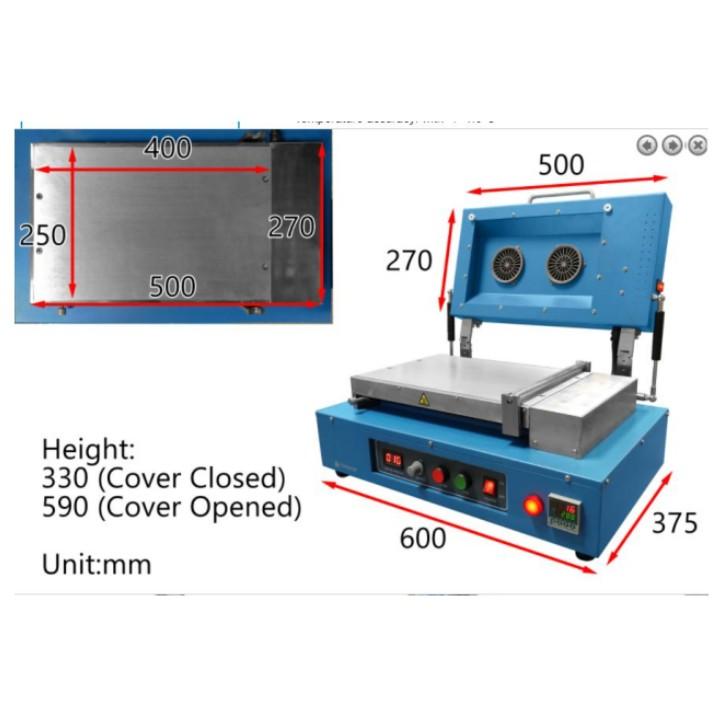

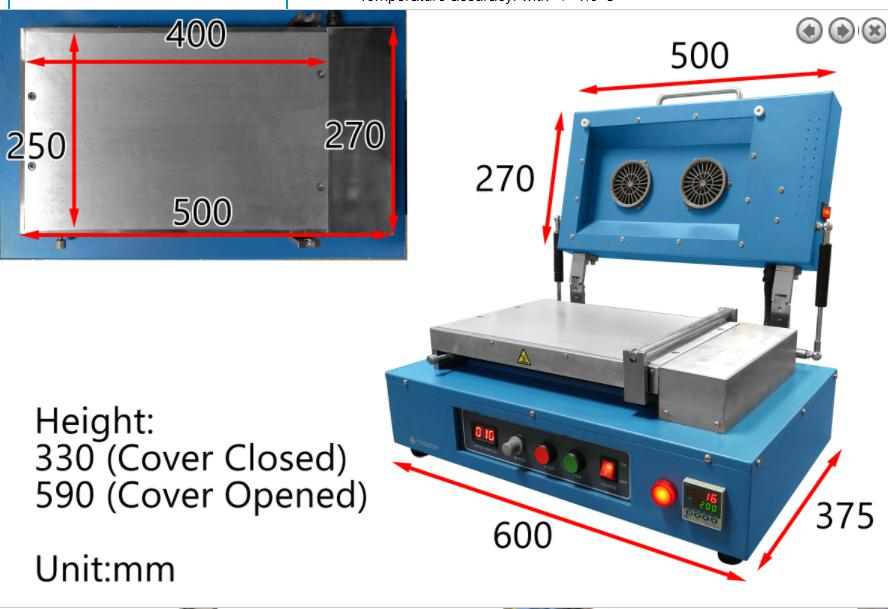

Heated vacuum suction plate: the material of vacuum suction plate is 6061 aluminum alloy with micron size holes on it Size of vacuum suction plate: 400mm(L) x 250mm(W) The heating element is installed in the vacuum suction plate, the highest temperature can reach 300℃ Digital display type temperature control meter, temperature control accuracy can reach +/-1℃ |

|

|

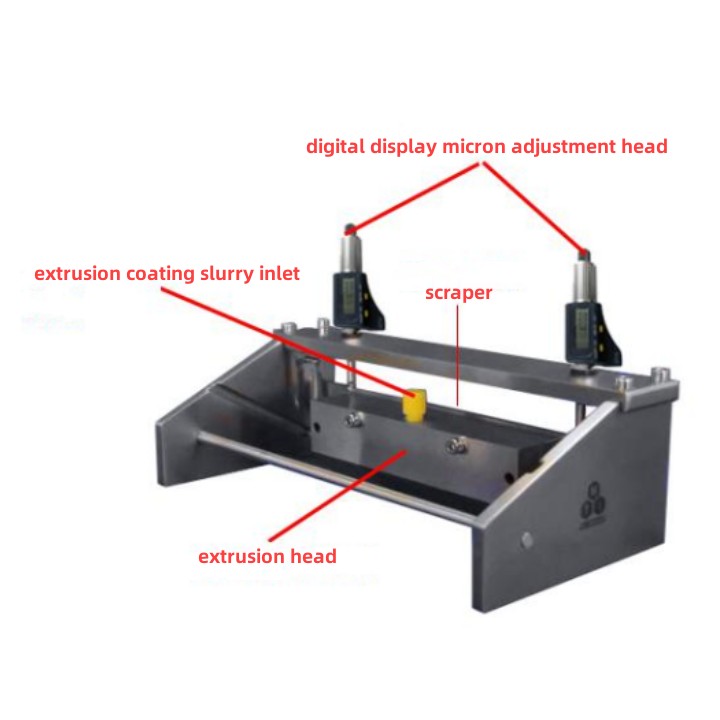

Modifiable film squeegee (squeegee): a push bar is installed to move the modifiable film squeegee A 180 mm wide, adjustable thickness (micrometer adjustment) modulator is standard (Figure 1) Optional hybrid film maker for cast coating and extrusion coating (Figure 2) 24V DC motor drive, so it can be used in the glove box under Ar environment

|

|

|

Cautions |

Users may need a viscosity tester to achieve repeatability of the experimental coating (Figure 1) After coating, the film can be rolled on a roller mill to achieve better compaction density (Figure 2)

|

|

Size |

|

|

Optional Accessories |

Double-stage rotary vane vacuum pump can be purchased from our company

|

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported