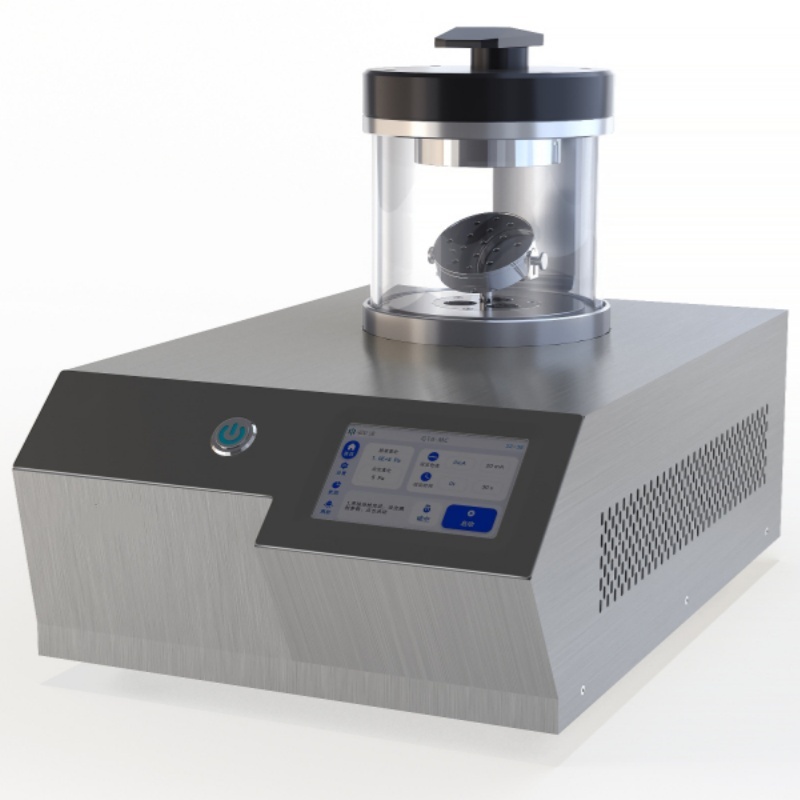

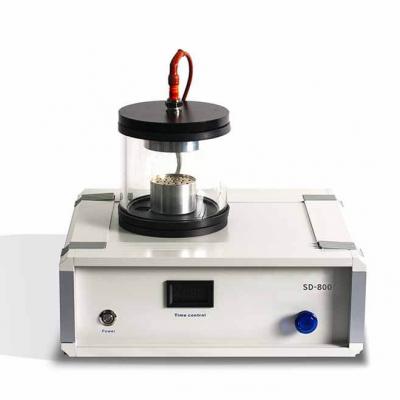

Au/Carbon Magnetron Sputter Depostion Coater Machine PVD System For SEM

Model: Lith-HZ-JS03- Au/Carbon Coating Magnetron Sputter Coater

Product Overview

The Lith-HZ-JS03 Dual-Target Magnetron Ion Sputtering Coater, independently developed with cutting-edge technology, sets a new benchmark for sample preparation instruments. It integrates dual-target co-sputtering and multi-layer single-sputtering capabilities, featuring a standard rotating/tilting module for multi-angle, uniform film coverage. This design eliminates charging effects, enhances sample contrast, and delivers high-resolution, true-to-life morphological characterization—ideal for advanced material science and biological research.

Technical Specifications

Category

Parameter

Specification

Core Parameters

Model

HZ-JS03

Vacuum Chamber (mm)

160 × 120

Sputtering Voltage

300–700 V

Sample Stage (mm)

Adjustable 80–100 diameter

Sputtering Type

Magnetron

Working Vacuum

2–10 Pa

System Configuration

Power Supply

100–250 VAC, 50/60 Hz

Target Size (mm)

φ50 × 0.1

Control System

5" Touchscreen (ARM)

Max. Power Consumption

100 W

Process Control

Sputtering Current

10–50 mA (±1 mA)

Sputtering Time

0–600 s (±1 s)

Ultimate Vacuum

<1 Pa

Safety & Monitoring

Vacuum Measurement

Digital Pirani Gauge

Protection

Current/Vacuum interlock

Instrument Highlights

1. SEM-Optimized Coating Performance

· Dual-target configuration: Enables sequential Au/Pt and Carbon deposition without breaking vacuum

· 2-10Pa working vacuum: Specialized for minimum oxidation during conductive coating

· <5nm particle size: Finer than conventional sputter coaters (typically 10-20nm)

2. Intelligent Process Control

· 300-700V voltage range with 1mA precision – 30% wider than standard systems for optimal film density

· Real-time plasma monitoring prevents arcing on sensitive samples

3. Ergonomic Design

· 160mm large chamber: Accommodates tall SEM stubs (up to 25mm) and irregular specimens

· Tool-free target change

Target Applications

▸ Life Science: Coating for pollen, plant tissues, and hydrated biological samples

▸ Materials Research: Nanowires, polymer films, and porous materials

▸ Failure Analysis: PCB cross-sections and insulating components

Operational Advantages

· One-cycle coating: 12 samples/batch (50% more than competitors)

· Zero thermal damage: Magnetron confinement keeps samples <40°C

· Self-diagnostics: Automatic pump protection and target life counter

|

Category |

Parameter |

Specification |

|

Core Parameters |

Model |

HZ-JS03 |

|

|

Vacuum Chamber (mm) |

160 × 120 |

|

|

Sputtering Voltage |

300–700 V |

|

|

Sample Stage (mm) |

Adjustable 80–100 diameter |

|

|

Sputtering Type |

Magnetron |

|

|

Working Vacuum |

2–10 Pa |

|

System Configuration |

Power Supply |

100–250 VAC, 50/60 Hz |

|

|

Target Size (mm) |

φ50 × 0.1 |

|

|

Control System |

5" Touchscreen (ARM) |

|

|

Max. Power Consumption |

100 W |

|

Process Control |

Sputtering Current |

10–50 mA (±1 mA) |

|

|

Sputtering Time |

0–600 s (±1 s) |

|

|

Ultimate Vacuum |

<1 Pa |

|

Safety & Monitoring |

Vacuum Measurement |

Digital Pirani Gauge |

|

|

Protection |

Current/Vacuum interlock |

▸ Materials Research: Nanowires, polymer films, and porous materials

▸ Failure Analysis: PCB cross-sections and insulating components

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported