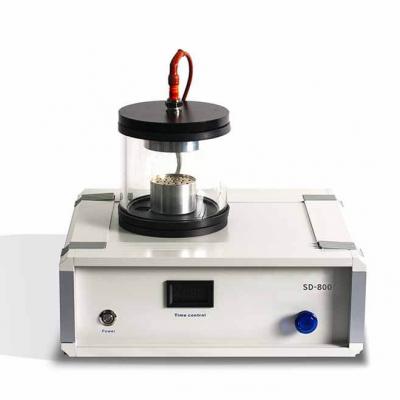

Small High Vacuum Magnetron Upward Sputtering Coater Coating Machine

I. Equipment Overview

1. Applicable: universities and colleges, research institutes and enterprises for scientific research and small batch preparation of new thin film materials.

2. Product features/uses:

► Small footprint, cheap price, stable performance and low cost of use and maintenance;

► Can be used to prepare single-layer and multi-layer metal film, dielectric film, magnetic film, sensor film and heat-resistant alloy film, hard film, corrosion-resistant film, etc;

► Coating examples: silver, aluminum, copper, nickel, chromium, nickel-chromium alloy, titanium oxide, ITO, silicon dioxide, etc;

► Single-target sputtering, multi-target sequential sputtering, common sputtering and other functions.

II. Technical parameters

|

Model |

JCP350 |

|

Vacuum chamber structure |

Vertical top-opening lid structure, rear extraction system, pneumatic lifting open type |

|

Vacuum chamber size |

Φ350×H350mm |

|

Heating temperature |

Room temperature~500℃ |

|

Sputtering method |

Upward sputtering |

|

Rotating substrate table |

Φ120mm |

|

Film thickness non-uniformity |

Φ75mm range ≤±5.0% |

|

Sputtering target/evaporation electrode |

Φ2 inch magnetron target 2pcs, compatible with DC/RF sputtering |

|

Process gas |

2-3 way gas flow control |

|

Control method |

PLC + touch screen human-machine interface semi-automatic control system |

|

Floor space |

(Host) L1600×W800×H1920mm |

|

Total power |

≥8KW |

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported