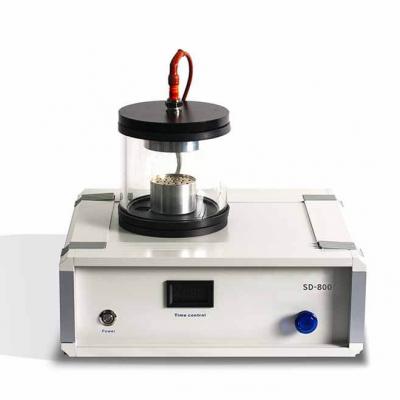

Small Auto Vaccum Carbon DC Sputter Coater

Model: Lith-BY-JS10 – Product Specifications

1. Technical Specifications Table

| Parameter | Specification |

|---|---|

| Model Number | Lith-BY-JS10 |

| Vacuum Pump | Oil-required Rotary Vacuum Pump (Explicit oil filling needed) |

| Pumping Speed | 50Hz: 16 m³/h (4.4 L/s) • 60Hz: 19.2 m³/h (5.2 L/s) • 20% speed boost at 60Hz |

| Ultimate Vacuum | 2 Pa |

| Max Sputtering Current | 1.6A |

| Operating Pressure Range | 20 Pa – 8 Pa |

| Pump-Down Time | <5 min (to 2 Pa) |

| Vacuum Measurement Range | Atmospheric pressure to 2×10⁷ mbar |

| Gas Control System | Precision Gas Flow Controller |

| Chamber Specifications | Ø350 × 240mm (H) • Scratch-resistant quartz glass viewport |

| Target Specifications | Ø200mm • Materials: Au, Ag, Pt, Cu (noble/conductive metals) |

| Operation | Instruction manual guided |

| Dimensions/Weight | 490(L) × 400(W) × 590(H) mm • 70 kg |

| Power Requirements | Dual-voltage: AC 110V/60Hz (Americas) or AC 220V/50Hz (Europe/Asia) |

| Power Consumption | <1500W |

| Warranty & Support | 1-year limited warranty + lifetime technical support |

2. Key Features & Competitive Advantages

Precision-Oriented Design

- Dual-Frequency Pumping: Automatically adapts to 50Hz/60Hz power grids (19.2 m³/h vs 16 m³/h) for global compatibility.

- Scratch-Resistant Quartz Viewport: Ensures long-term visibility during deposition without degradation.

- Oil-Lubricated Vacuum Pump: Delivers stable 2 Pa base pressure (vs. dry pumps), critical for consistent thin-film quality.

Material Versatility

- Broad Target Compatibility: Supports Au/Ag/Pt/Cu targets for conductive/noble metal coatings.

- Rapid Process Setup: <5-minute pump-down enables efficient batch processing.

User-Centric Engineering

- Global Voltage Support: No external converter needed for 110V/220V operation.

- Compact Footprint: Benchtop design (0.49×0.4×0.59m) saves lab space.

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported