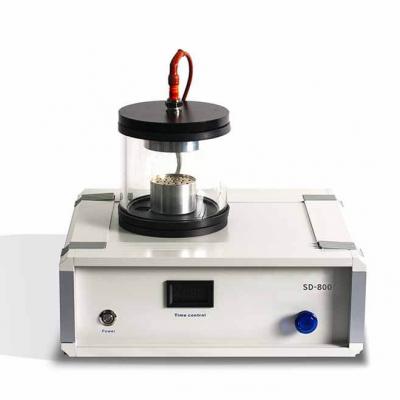

Multi-target Composite Magnetron Sputtering Film Deposition Coating System

Model: Lith-PC-JS10-Multi-target, Multi-film Deposition

Specifications

Category

Parameter

Primary Application

Nanoscale monolayer/multilayer films (hard coatings, metals, semiconductors, dielectrics)

Target Users

Universities, research institutes (R&D and small-batch production)

System Composition

Vacuum chamber, sputtering targets, sample stage, vacuum pumps, gas delivery, control systems, film thickness monitor, and auxiliary components

Vacuum Performance

Parameter

Specification

Ultimate Vacuum

6.7 × 10-5 Pa

System Leak Rate

≤1 × 10-7 Pa·L/s

Vacuum Recovery Time

≤40 min (to 6.6 × 10-1 Pa after N2 purge)

Chamber & Sample Stage

Component

Specification

Chamber Dimensions

Ø630 mm × 350 mm (cylindrical)

Sample Capacity

8 × 4-inch substrates (1 mm thickness)

Sputtering Targets

Feature

Specification

Target Types

3 × Permanent magnet targets, 3 × High-intensity magnet targets

Cooling Method

Indirect water-cooled (brazed structure)

Target Diameter

Ø100 mm

Target-Substrate Distance

50–90 mm (manual adjustment, with position indicator)

Sputtering Mode

Vertical downward sputtering

Substrate Control

Parameter

Specification

Bias Voltage

Up to -200 V

Rotation Mechanism

Computer-controlled revolution + rotation (stepper motor-driven)

Temperature Control

RT to 300°C (single calibration required; 3 heaters, one active at a time)

Gas & Thickness Control

Component

Specification

Mass Flow Controllers (MFC)

2 channels

Film Thickness Monitor

Quartz crystal microbalance (0–999,999 Å)

Pumping Options

Configuration

Components

Standard

Turbo molecular pump + dry scroll pump

Alternative

Cryogenic pump + dry scroll pump

Computer Control Features

· Real-time displacement/speed monitoring with error calculation.

· Linear/logarithmic display modes for speed vs. displacement.

· Site-specific deposition via precision positioning.

Key Advantages & Applications

✔ Multi-Target Flexibility – Supports diverse materials (metals, oxides, nitrides).

✔ Uniform Deposition – Computer-controlled rotation ensures film consistency.

✔ High Vacuum Stability – Minimizes contamination for high-purity films.

✔ Research-Ready – Modular design suits optoelectronics, tribological coatings, and semiconductor R&D.

Ideal for: Advanced material science studies and prototyping of functional thin-film devices.

Specifications

|

Category |

Parameter |

|

Primary Application |

Nanoscale monolayer/multilayer films (hard coatings, metals, semiconductors, dielectrics) |

|

Target Users |

Universities, research institutes (R&D and small-batch production) |

|

System Composition |

Vacuum chamber, sputtering targets, sample stage, vacuum pumps, gas delivery, control systems, film thickness monitor, and auxiliary components |

Vacuum Performance

|

Parameter |

Specification |

|

Ultimate Vacuum |

6.7 × 10-5 Pa |

|

System Leak Rate |

≤1 × 10-7 Pa·L/s |

|

Vacuum Recovery Time |

≤40 min (to 6.6 × 10-1 Pa after N2 purge) |

Chamber & Sample Stage

|

Component |

Specification |

|

Chamber Dimensions |

Ø630 mm × 350 mm (cylindrical) |

|

Sample Capacity |

8 × 4-inch substrates (1 mm thickness) |

Sputtering Targets

|

Feature |

Specification |

|

Target Types |

3 × Permanent magnet targets, 3 × High-intensity magnet targets |

|

Cooling Method |

Indirect water-cooled (brazed structure) |

|

Target Diameter |

Ø100 mm |

|

Target-Substrate Distance |

50–90 mm (manual adjustment, with position indicator) |

|

Sputtering Mode |

Vertical downward sputtering |

Substrate Control

|

Parameter |

Specification |

|

Bias Voltage |

Up to -200 V |

|

Rotation Mechanism |

Computer-controlled revolution + rotation (stepper motor-driven) |

|

Temperature Control |

RT to 300°C (single calibration required; 3 heaters, one active at a time) |

Gas & Thickness Control

|

Component |

Specification |

|

Mass Flow Controllers (MFC) |

2 channels |

|

Film Thickness Monitor |

Quartz crystal microbalance (0–999,999 Å) |

Pumping Options

|

Configuration |

Components |

|

Standard |

Turbo molecular pump + dry scroll pump |

|

Alternative |

Cryogenic pump + dry scroll pump |

Computer Control Features

· Real-time displacement/speed monitoring with error calculation.

· Linear/logarithmic display modes for speed vs. displacement.

· Site-specific deposition via precision positioning.

Key Advantages & Applications

✔ Multi-Target Flexibility – Supports diverse materials (metals, oxides, nitrides).

✔ Uniform Deposition – Computer-controlled rotation ensures film consistency.

✔ High Vacuum Stability – Minimizes contamination for high-purity films.

✔ Research-Ready – Modular design suits optoelectronics, tribological coatings, and semiconductor R&D.

Ideal for: Advanced material science studies and prototyping of functional thin-film devices.

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported