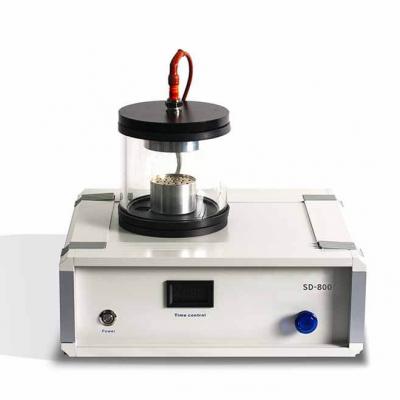

High Vacuum Magnetron Sputtering Deposition PVD System For Multilayer & Multitarget

Model: Lith-PC-JS07-High Vacuum & Multilayer & Multitarget

Key Features & Applications

The Lith-PC-JS07 is designed for nano-scale single-layer and multilayer functional films, including hard coatings, metallic films, semiconductor layers, and dielectric films. Ideal for research institutions and universities, it supports both material science studies and small-batch production.

System Components

· Vacuum chamber system (sputtering chamber)

· Target & power supply system

· Sample stage system

· Vacuum pumping & measurement system

· Gas flow system

· Control system

· Film thickness monitoring system

· Top cover lifting mechanism

· Electrical control system

· Computer-controlled system & auxiliary components

Technical Specifications

Parameter

Value

Ultimate Vacuum

6.7×10-5 Pa

System Leak Rate

1×10-7 Pa·L/S

Vacuum Recovery Time

≤40 min to 6.6×10 Pa (after N2 purge)

Chamber Design

Round chamber, Ø450×350 mm

Sample Stage

3-inch × 3-inch (3.2 mm thick)

Heating Temperature

600°C ±1°C (programmable)

Sample Rotation

Self-rotation: 0–50 RPM (uniformity)

Revolution: Position-switching capability

Magnetron Target

3 targets (standard)

Effective Sputtering Area: 3-inch × 3-inch

Type: Permanent magnet, brazed indirect water-cooled

Deposition Mode

Upward sputtering (planar target)

Substrate Bias Voltage

Up to –200 V

Gas Flow System

2-channel mass flow controller

Thickness Monitor

Quartz crystal sensor (0–999,999 Å)

Pumping Options

Turbo molecular pump / Cryogenic pump + Dry scroll pump

Control & Automation

· Real-time monitoring: Tracks displacement and revolution speed.

· Error analysis: Displays deviations via curves/numerical data.

· Flexible display: Switch between linear and logarithmic scales for revolution speed vs. displacement.

· Advanced modes: Supports fixed-point deposition and resistive evaporation coating.

Why Choose?

✔ High Precision: Programmable heating (±1°C) and dual-axis sample motion ensure uniform film growth.

✔ Versatile Configurations: Compatible with multiple target materials and pumping systems.

✔ Research-Oriented: Combines in-situ thickness control with automated process logging for reproducible results.

Ideal for: Advanced material research, optical coatings, semiconductor layers, and protective coatings development.

|

Parameter |

Value |

|

Ultimate Vacuum |

6.7×10-5 Pa |

|

System Leak Rate |

1×10-7 Pa·L/S |

|

Vacuum Recovery Time |

≤40 min to 6.6×10 Pa (after N2 purge) |

|

Chamber Design |

Round chamber, Ø450×350 mm |

|

Sample Stage |

3-inch × 3-inch (3.2 mm thick) |

|

Heating Temperature |

600°C ±1°C (programmable) |

|

Sample Rotation |

Self-rotation: 0–50 RPM (uniformity) Revolution: Position-switching capability |

|

Magnetron Target |

3 targets (standard) Effective Sputtering Area: 3-inch × 3-inch Type: Permanent magnet, brazed indirect water-cooled |

|

Deposition Mode |

Upward sputtering (planar target) |

|

Substrate Bias Voltage |

Up to –200 V |

|

Gas Flow System |

2-channel mass flow controller |

|

Thickness Monitor |

Quartz crystal sensor (0–999,999 Å) |

|

Pumping Options |

Turbo molecular pump / Cryogenic pump + Dry scroll pump |

✔ Versatile Configurations: Compatible with multiple target materials and pumping systems.

✔ Research-Oriented: Combines in-situ thickness control with automated process logging for reproducible results.

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported