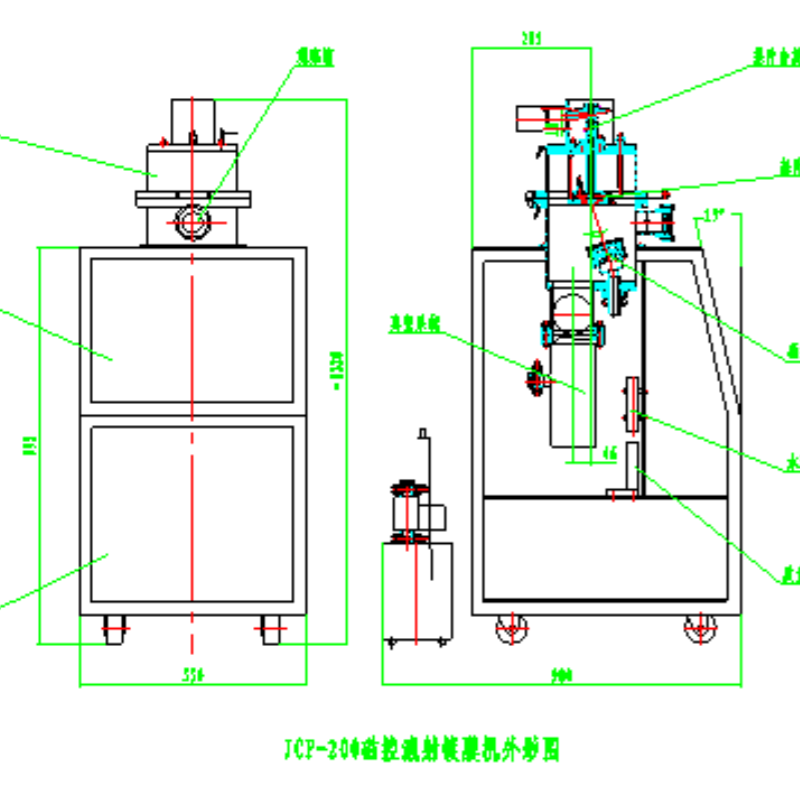

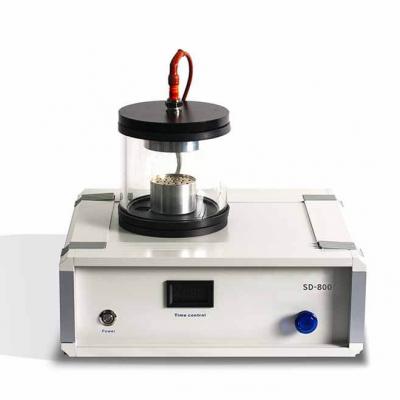

High-Precision Multi-Target Magnetron Sputter Coating System Coater

Model: Lith-PC-JS11 – Product Specifications

Specifications

| Category | Parameter | Details |

|---|---|---|

| Vacuum Performance | Ultimate Vacuum (Sputtering Chamber) | ≤6.6×10⁻⁶ Pa |

| System Leak Rate | ≤5.0×10⁻⁷ Pa·L/S | |

| Pump-Down Time (Atmosphere → 6.6×10⁻⁴ Pa) | ≤30 min | |

| Vacuum Retention (After 12 Hours Shutdown) | ≤5 Pa | |

| Sputtering Chamber | Structure | Vertical, top-opening, stainless steel (argon-welded, electropolished) |

| Dimensions | ≥Ø300 mm × 300 mm (with anti-contamination liner) | |

| Bakeability & Sealing | 100–150°C; metal gasket/fluororubber O-ring | |

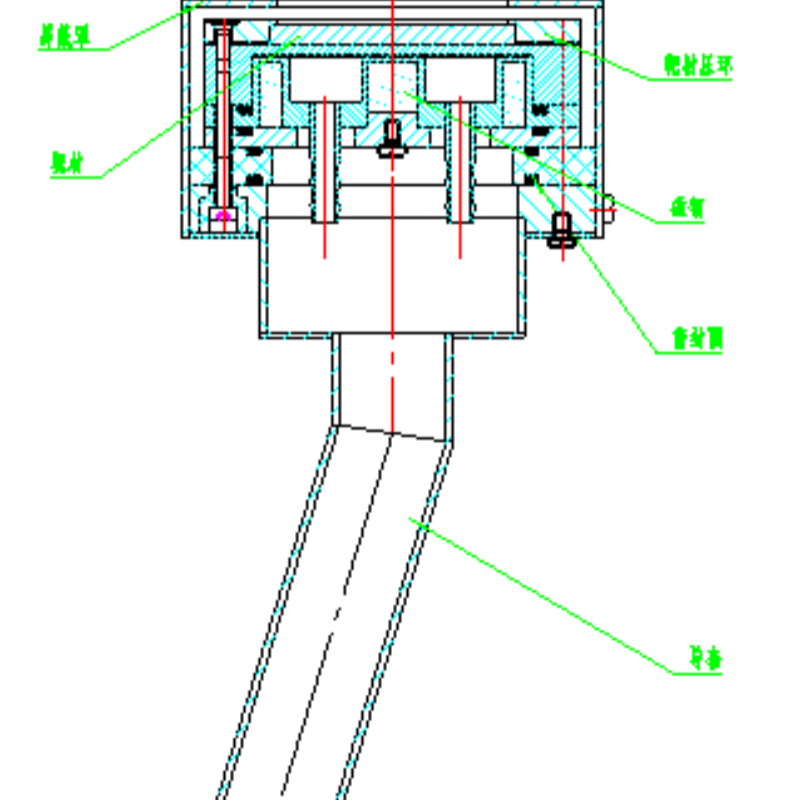

| Magnetron Sputtering | Target Configuration | 3 × 50 mm adjustable-angle permanent magnet targets (RF/DC/MF compatible) |

| Power Supply | 2 × DC (≥500 W), 1 × auto-matching RF (≥500 W) | |

| Film Uniformity | ≤5% deviation | |

| Additional Features | 3 × SMC rotary shutters; magnetic material support | |

| Substrate Stage | Sample Capacity | 1 × ≥100 mm diameter |

| Rotation Speed | 0–30 RPM (adjustable) | |

| Heating Range | RT–500°C (PID-controlled, thermocouple feedback) | |

| Gas Delivery | Mass Flow Control | 2 paths (100 SCCM + 20 SCCM MFCs, CF16 valves) |

| Auxiliary Gas Lines | 2 × DN16 inlet valves | |

| Pumping System | High-Vacuum Pump | Pfeiffer Hipace 700 (680 L/s) + 4 L/s rotary pump |

| Valves & Pipeline | DN40/CC150 pneumatic valves, stainless steel bellows | |

| Control & Safety | Automation | PLC + industrial PC + touchscreen (real-time monitoring/logging) |

| Protection | Interlocks for water/power faults (overcurrent, open circuit, etc.) | |

| Additional Components | Frame | Steel construction, lockable casters, removable panels |

| Included Accessories | Chiller, silent compressor, tool kit, spare parts | |

| Measurement | Vacuum Gauge | INFICON combination gauge |

Key Advantages & Applications

Advantages:

-

High Precision: Ultra-high vacuum (UHV) capability ensures contamination-free thin-film deposition.

-

Flexibility: Multi-target configuration with adjustable parameters for diverse materials (including magnetic films).

-

Reliability: Robust PLC automation with fail-safe interlocks and real-time diagnostics.

-

User-Friendly: Integrated touchscreen and PC control streamline operation.

Target Applications:

-

Research & Development: Ideal for academic or industrial labs studying advanced coatings (e.g., semiconductors, optics).

-

Industrial Coating: Suitable for small-scale production of functional films (wear-resistant, conductive, or decorative layers).

-

Material Science: Supports experiments requiring controlled environments (e.g., reactive sputtering, multi-layer deposition).

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported