Five Target Plasma RF Magnetron Sputtering Coater Instrument

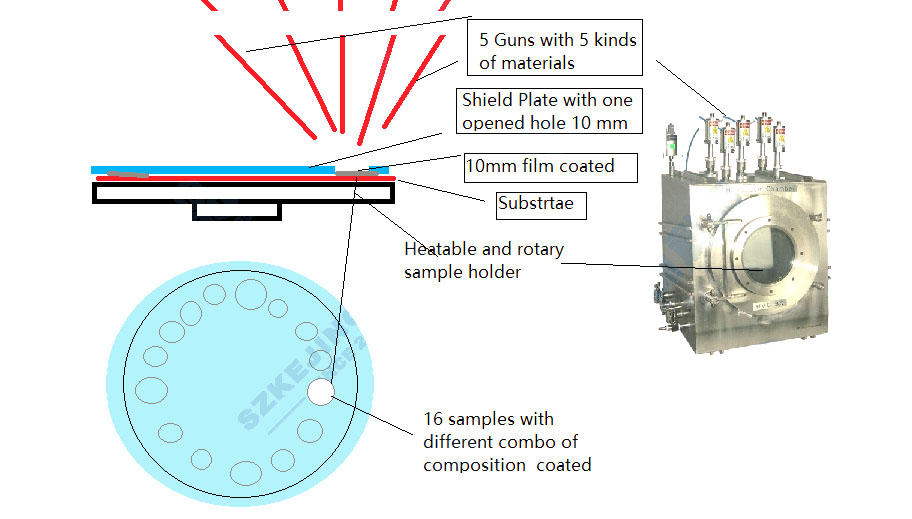

Application: VTC-5RF is a 5-target plasma RF magnetron sputtering instrument for the study of high-throughput MGI(Materials Genome Project) thin films. It is particularly suitable for the exploration of solid electrolyte materials, through 5 elements, in 16 different combinations

|

Performance indicators and basic configuration |

|

|

Main features |

● A variety of sputtering targets and power supplies are available for free combination, please call our sales department for details. ● Depending on the power supply used (DC or RF), metallic or non-metallic materials can be deposited. ● A rotary switch activates the sputtering heads in sequence, which can be switched automatically in a vacuum or plasma environment without affecting the vacuum level. ● Five targets of different materials can be installed, and parameters such as sputtering time and power can be set individually for each target head for growing thin films of different compositions. ● Multiple RF power supplies can be purchased to sputter multiple targets at the same time. ● Optional equipment control software is available to control all parameters of sputtering by computer. |

|

Sputtering chamber |

● Vacuum chamber is made of 304 stainless steel. ● Chamber internal dimensions: 470mm L x 445mm D x 522mm H (105 L).

● Hinged chamber door, diameter Φ380mm, with Φ150mm glass window mounted on top. |

|

Sputter heads & href="javascript:;" specimen stage |

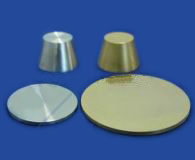

● Five 1-inch magnetron sputtering heads with water-cooled interlayers (Fig. 1)

● Motorised baffles fitted in the sputtering chamber ● Sputtering distance: adjustable sputtering distance ● Sputtering angle: adjustable sputtering angle ● The target and the copper spacer of the target need to be bonded with conductive silver paste (conductive silver paste can be purchased from our company) ● The RF connection cable can be ordered separately as a spare (Figure 2)

● The equipment requires a water cooler for target head cooling (Figure 3)

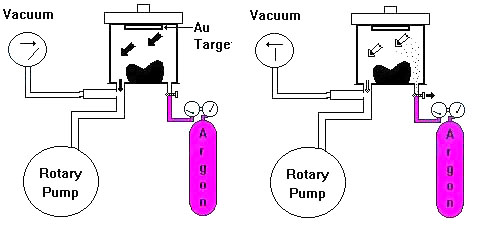

● Please refer to the schematic diagram (Figure 4)

|

|

Specimen stage |

● Sample table with a diameter of 150mm, covered with a rotating table with a 10mm hole to expose one sample at a time to receive sputtered films. ● Sample stage size: Φ150mm, can be rotated by programme control, can produce 16 different components of film.

● The table can be heated to a maximum temperature of 600°C. |

|

Vacuum system |

● KF40 vacuum connection installed ● Vacuum level: 4.0e-5Torr (molecular pump) (reference value, please click)

● Various vacuum pumps can be purchased from us. |

|

Air inlet |

● The unit is equipped with a 1/4 inch air inlet for easy connection to a gas cylinder. ● An airflow adjustment knob on the front panel of the unit for easy adjustment of airflow. |

|

Target materials |

● Required target size: 25mm in diameter and 3mm in thickness at most.

● Various target materials are available at our company. |

|

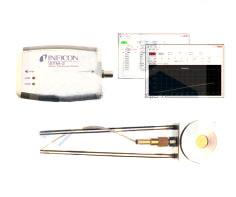

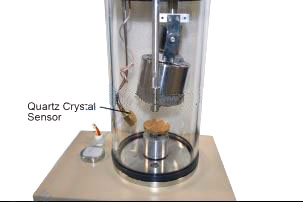

Film thickness gauge (optional) |

Thin Film Thickness Gauge can be purchased to be installed on the sputter meter. |

|

Net weight |

60 kg(Pumps not included) |

|

Tips |

● This is a DIY equipment, the parameters vary greatly, please be sure to call before purchasing to discuss carefully. ● For good film quality, high purity gas (> 5N recommended) must be fed in. ● Make sure that the sputter head, target, substrate and sample stage are clean before sputtering. ● Clean the substrate surface before sputtering to achieve a good bonding of the film to the substrate.● Ultrasonic cleaning (for detailed parameters click on the picture below): (1) Acetone ultrasonic (2) Isopropyl alcohol ultrasonic - removes oil and grease (3) Blow Nitrogen drying (4) Vacuum oven to remove moisture. ● Plasma cleaning (for detailed parameters click on the picture below): surface roughening, activation of chemical bonds on the surface, removal of additional contaminants. ● Creating a thin buffer layer (around 5nm): e.g. Gr, Ti, Mo, Ta, can be applied to improve the adhesion of metals and alloys.

Ultrasonic cleaner

Plasma cleaner

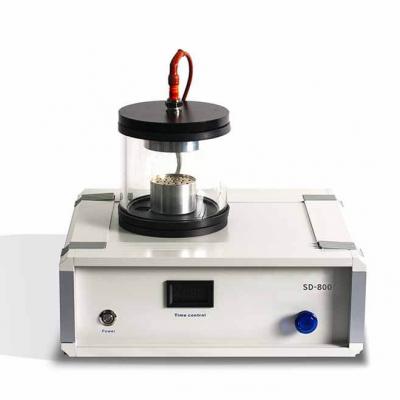

Vapour plating machine

Glove box

|

|

Warn |

● Note: The product is installed with high voltage components inside, it is prohibited to disassemble and move the body with electricity. ● A pressure-reducing valve should be installed on the gas cylinder (not included in the standard equipment) to ensure that the output pressure of the gas is limited to less than 0.02 MPa for safe use. ● The sputtering head is connected to a high voltage. For safety, the operator must load samples and change targets before switching off the equipment |

|

Certification |

CE certification |

|

Warranty period |

One year warranty and lifetime technical support. Special tips: 1. Consumable parts such as heating elements, quartz tubes, sample crucibles, etc. are not included. 2. Damage caused by the use of corrosive gases and acid gases is not covered by the warranty. |

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported