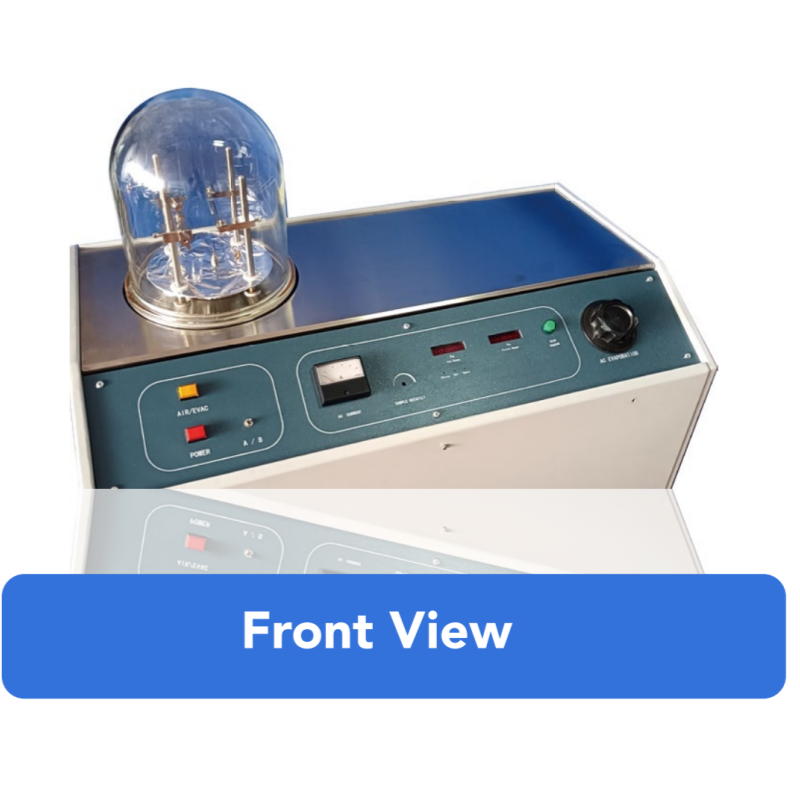

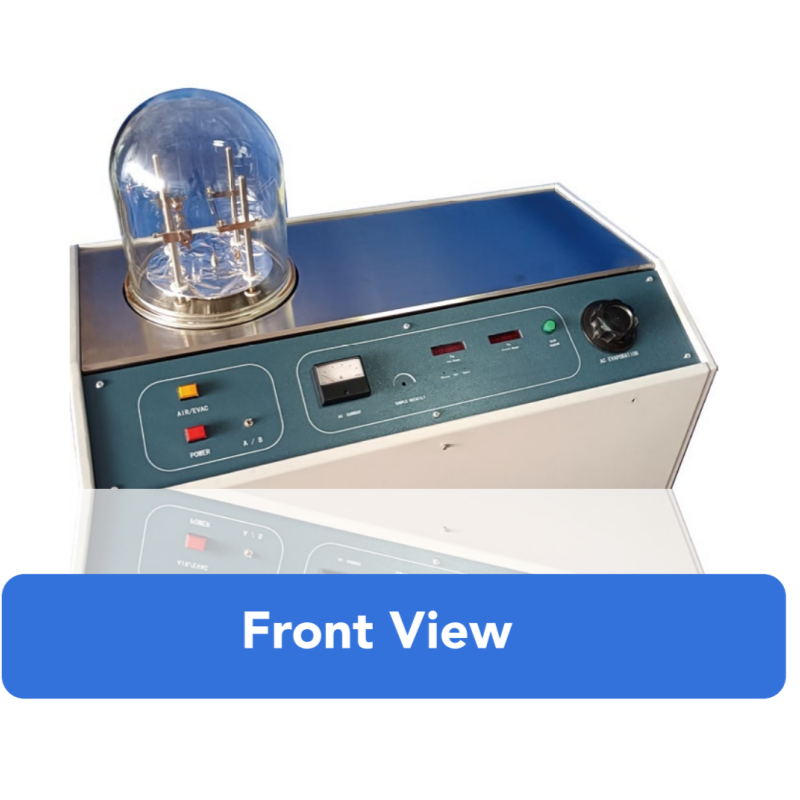

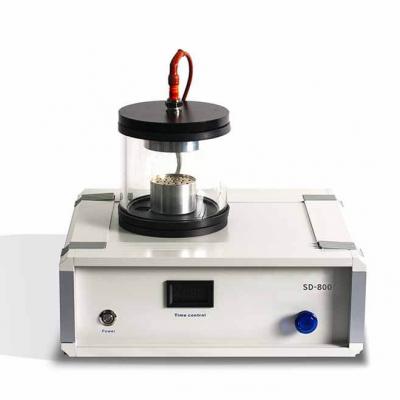

Dual-Source Vacuum Deposition Coating System Evaporation Coater For Metal/Organic Multilayer Thin Film

Lith-BY-ZD04-Dual-Source Vacuum Deposition

Technical Specifications

|

Parameter |

Specification |

|

Model |

Lith-BY-ZD04 |

|

Coating Method |

Multi-source metal evaporation |

|

Vacuum Chamber |

Glass bell jar + stainless steel base |

|

Chamber Dimensions |

Φ300mm × H360mm |

|

Substrate Heating |

Room temperature ~ 250°C |

|

Substrate Size |

Φ100mm |

|

Film Uniformity |

≤ ±5.0% (within Φ80mm area) |

|

Evaporation Sources |

2 independent metal sources |

|

Control System |

PLC + touchscreen interface |

|

Footprint |

L1100mm × W800mm (main unit) |

|

Power Requirement |

≥ 5kW |

Key Features & Competitive Analysis

1. Compact & High Cost-Performance

· Compared to larger industrial systems, the offers a space-saving integrated design, making it ideal for labs with limited space.

· Lower operational costs due to efficient power usage and minimal maintenance needs.

2. Dual-Source Deposition Flexibility

· Many basic models offer only single-source evaporation, limiting material options. The ZHD300’s dual-source configuration enables:

o Co-evaporation: Producing alloy or doped films (e.g., metal-oxide composites).

o Sequential evaporation: Depositing multilayer structures (e.g., electrode/interlayer/active layers for solar cells).

· Superior to thermal evaporation-only systems, as it supports both organic and inorganic materials.

3. Precision & Reproducibility

· ±5% thickness uniformity outperforms many entry-level systems (typically ±8–10%), ensuring research-grade consistency.

· PLC-controlled deposition reduces human error vs. manual systems.

4. Glove-Box Compatibility

· Unlike conventional stand-alone coaters, the can be integrated with glove-box workflows, critical for:

o Air-sensitive materials (e.g., perovskites, OLED emitters).

o In-line encapsulation, reducing contamination risks.

Target Applications vs. Alternatives

Application

Advantage

Alternatives

R&D on Solar Cells

Dual-source for graded/stacked layers

Single-source systems lack compositional control

OLED/Thin-Film Research

Organic-Inorganic compatibility

Dedicated organic evaporators (higher cost)

Pilot Production Trials

High uniformity meets pre-production standards

Industrial systems (over-sized for labs)

Conclusion: Ideal for Innovators

The Lith-BY-ZD04 bridges the gap between basic lab tools and industrial coaters, offering:

✔ Research versatility – Thin-film exploration with multi-material capability.

✔ Process reliability – Repeatable results for scalable R&D.

✔ Future-ready design – Glove-box integration for next-gen optoelectronics.

Engineered for advanced materials science, where precision meets adaptability.

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported