Benchtop DC/RF Magnetron Sputtering Conductive Coater For Metals, Oxides & Ceramics & Semiconductors

Model: Lith-PD-JS01-DC/RF Sputtering, Multi-Target, Uniform Coating (±5%), Fast Deposition

Product Overview

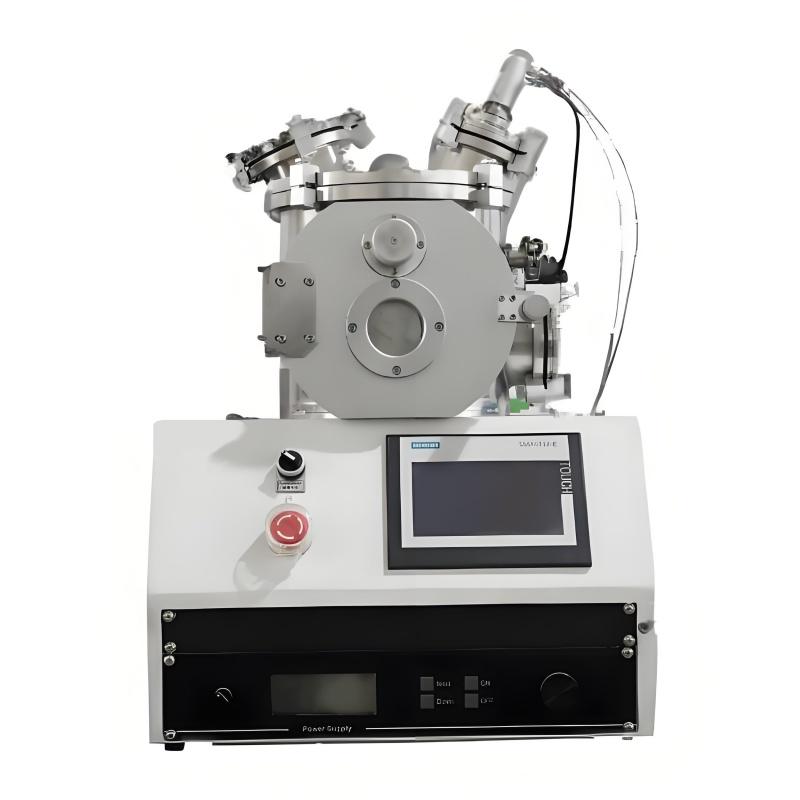

The Lith-PD-JS01 is a compact magnetron sputtering system designed for laboratory-scale thin-film deposition. Compatible with both DC and RF sputtering sources, it supports the coating of metals, non-metals, and compound films (e.g., ITO). Ideal for academic and industrial research, it enables the preparation of single/multilayer films and facilitates advanced material/process development.

Key Features

1. Robust Construction

·All-stainless-steel vacuum chamber ensures durability and operational safety.

·Optimized gas path design for enhanced process control.

2. Space-Efficient & Modular

·Compact footprint (500×360×380mm) with modular expandability, maximizing lab space utilization.

3. High-Efficiency Vacuum System

·Hybrid mechanical + imported molecular pump achieves high vacuum (≤3×10⁻⁵ Pa) in 15–20 minutes, reducing downtime.

4. Precision Process Control

·Uniformity: ≤±5% over Ø80mm substrate area.

·Rotating Substrate Holder: Adjustable speed (0–20 RPM) with magnetic fluid sealing for stable deposition.

5. Flexible Configuration

·Sputtering Sources: 2–3 × 2-inch targets (DC/mid-frequency/RF).

·Gas System: 1–3 gas inlets with ±1% flow accuracy (20 sccm).

Technical Specifications

Parameter

Specification

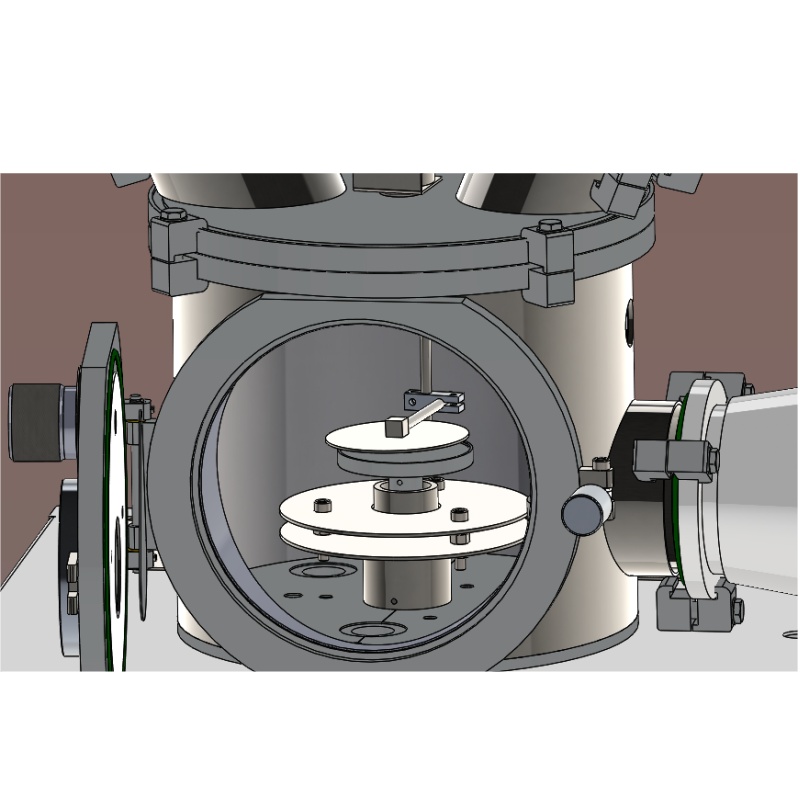

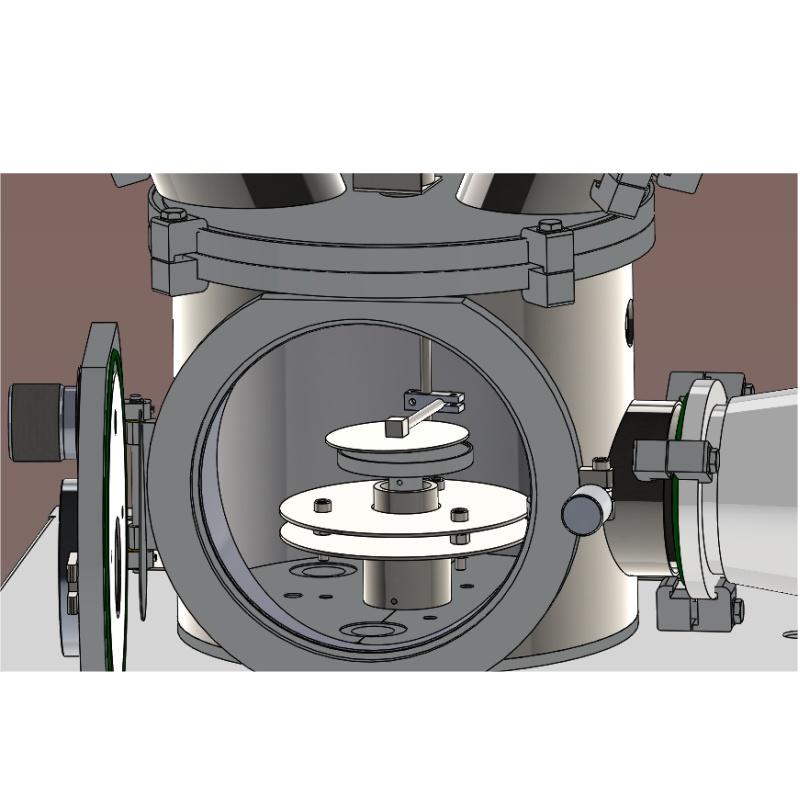

Vacuum Chamber

Ø260 × H280mm (304 stainless steel, cylindrical, viewport)

Vacuum System

Mechanical pump + imported molecular pump

Base Pressure

≤3×10⁻⁵ Pa

Pump-down Time

≤3×10⁻⁴ Pa in 15min

Substrate Holder

Max. Ø80mm, rotation speed 0–20 RPM (adjustable)

Sputtering Sources

2–3 × 2-inch targets; 1KW DC/mid-frequency/RF power supply

Uniformity

≤5% (Ø80mm area)

Gas Control

1–3 channels, ±1% accuracy (20 sccm max)

Control Mode

Manual button or PLC touchscreen (with safety interlocks)

Power Supply

AC220V/50Hz, 2.5KW

Dimensions (L×W×H)

500 × 360 × 380mm

Optional Upgrades: Substrate heating/cooling, dry pump, additional flow meters, water chiller.

Target Applications

· Research: Thin-film studies (metals, oxides, semiconductors).

· Education: Lab demonstrations and student projects.

· Industry: Prototyping for electronics, optics, and energy materials (e.g., ITO for solar cells).

Why Choose?

· Fast turnaround: Rapid pump-down accelerates experimental cycles.

· Scalable: Modular design adapts to evolving research needs.

· User-centric: Intuitive controls and safety features streamline operation.

Product Overview

The Lith-PD-JS01 is a compact magnetron sputtering system designed for laboratory-scale thin-film deposition. Compatible with both DC and RF sputtering sources, it supports the coating of metals, non-metals, and compound films (e.g., ITO). Ideal for academic and industrial research, it enables the preparation of single/multilayer films and facilitates advanced material/process development.

Key Features

1. Robust Construction

·All-stainless-steel vacuum chamber ensures durability and operational safety.

·Optimized gas path design for enhanced process control.

2. Space-Efficient & Modular

·Compact footprint (500×360×380mm) with modular expandability, maximizing lab space utilization.

3. High-Efficiency Vacuum System

·Hybrid mechanical + imported molecular pump achieves high vacuum (≤3×10⁻⁵ Pa) in 15–20 minutes, reducing downtime.

4. Precision Process Control

·Uniformity: ≤±5% over Ø80mm substrate area.

·Rotating Substrate Holder: Adjustable speed (0–20 RPM) with magnetic fluid sealing for stable deposition.

5. Flexible Configuration

·Sputtering Sources: 2–3 × 2-inch targets (DC/mid-frequency/RF).

·Gas System: 1–3 gas inlets with ±1% flow accuracy (20 sccm).

Technical Specifications

Parameter

Specification

Vacuum Chamber

Ø260 × H280mm (304 stainless steel, cylindrical, viewport)

Vacuum System

Mechanical pump + imported molecular pump

Base Pressure

≤3×10⁻⁵ Pa

Pump-down Time

≤3×10⁻⁴ Pa in 15min

Substrate Holder

Max. Ø80mm, rotation speed 0–20 RPM (adjustable)

Sputtering Sources

2–3 × 2-inch targets; 1KW DC/mid-frequency/RF power supply

Uniformity

≤5% (Ø80mm area)

Gas Control

1–3 channels, ±1% accuracy (20 sccm max)

Control Mode

Manual button or PLC touchscreen (with safety interlocks)

Power Supply

AC220V/50Hz, 2.5KW

Dimensions (L×W×H)

500 × 360 × 380mm

Optional Upgrades: Substrate heating/cooling, dry pump, additional flow meters, water chiller.

Target Applications

· Research: Thin-film studies (metals, oxides, semiconductors).

· Education: Lab demonstrations and student projects.

· Industry: Prototyping for electronics, optics, and energy materials (e.g., ITO for solar cells).

Why Choose?

· Fast turnaround: Rapid pump-down accelerates experimental cycles.

· Scalable: Modular design adapts to evolving research needs.

· User-centric: Intuitive controls and safety features streamline operation.

|

Parameter |

Specification |

|

Vacuum Chamber |

Ø260 × H280mm (304 stainless steel, cylindrical, viewport) |

|

Vacuum System |

Mechanical pump + imported molecular pump |

|

Base Pressure |

≤3×10⁻⁵ Pa |

|

Pump-down Time |

≤3×10⁻⁴ Pa in 15min |

|

Substrate Holder |

Max. Ø80mm, rotation speed 0–20 RPM (adjustable) |

|

Sputtering Sources |

2–3 × 2-inch targets; 1KW DC/mid-frequency/RF power supply |

|

Uniformity |

≤5% (Ø80mm area) |

|

Gas Control |

1–3 channels, ±1% accuracy (20 sccm max) |

|

Control Mode |

Manual button or PLC touchscreen (with safety interlocks) |

|

Power Supply |

AC220V/50Hz, 2.5KW |

|

Dimensions (L×W×H) |

500 × 360 × 380mm |

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported