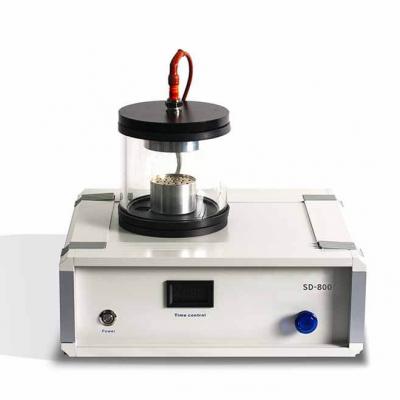

3D Magnetron Sputtering PVD Coating System For SEM Sample Preparation

Model: Lith-ZK-JS04- DC Ion Sputtering Coater

Technical Specifications

Parameter

Specification

Target Materials

Standard: Au (Gold), 57mm diameter × 0.1mm thick

Optional: Pt (Platinum)

Standard Sample Holder

Holds 12 SEM stubs, height adjustment range: 60mm

Rotating/Tilting Stage (Optional)

Rotation: 0–60 rpm (continuously adjustable)

Tilt: -90° to +90° (continuously adjustable)

Standard rotating platform: 40mm diameter (holds 4 sample holders, custom sizes available)

Dual locking mechanism for secure fixation

Sputtering Current

5–30mA (microprocessor-controlled, programmable)

Meters

Vacuum: Atm – 1×10⁻³ mbar

Current: 0–99mA

Control Method

Microprocessor with Start/Pause buttons

Programmable time (1–999s)

Auto-pumping, sputtering, and venting

Vacuum System

Pumping speed: 133 L/min

Ultimate vacuum: 10⁻⁴ mbar

Noise level: 56 dB

Key Features & Applications

1. Precision and Flexibility

· Adjustable sputtering current (5–30mA) and rotating/tilting stage enable uniform thin-film deposition for diverse sample geometries.

· Dual locking mechanism prevents sample displacement during operation.

2. High-Quality Coating

· Gold (Au) and Platinum (Pt) targets ensure high-purity conductive coatings for SEM and analytical applications.

3. Automated & User-Friendly Operation

· Programmable controls and auto-venting enhance efficiency and safety.

4. Compact & Low-Noise Design

· Stainless steel chamber (120mm × 75mm) with observation window (120mm × 45mm) provides durability and visibility.

· Low 56 dB noise level ensures a comfortable working environment.

Ideal Applications

· SEM sample preparation (conductive coating)

· Thin-film deposition for research and industrial applications

· Multi-sample processing (supports 12 SEM stubs)

· Angle-dependent deposition (with optional rotating/tilting stage)

This sputtering system is optimized for laboratories requiring high precision, automation, and versatile coating capabilities.

Technical Specifications

Parameter

Specification

Target Materials

Standard: Au (Gold), 57mm diameter × 0.1mm thick

Optional: Pt (Platinum)

Standard Sample Holder

Holds 12 SEM stubs, height adjustment range: 60mm

Rotating/Tilting Stage (Optional)

Rotation: 0–60 rpm (continuously adjustable)

Tilt: -90° to +90° (continuously adjustable)

Standard rotating platform: 40mm diameter (holds 4 sample holders, custom sizes available)

Dual locking mechanism for secure fixation

Sputtering Current

5–30mA (microprocessor-controlled, programmable)

Meters

Vacuum: Atm – 1×10⁻³ mbar

Current: 0–99mA

Control Method

Microprocessor with Start/Pause buttons

Programmable time (1–999s)

Auto-pumping, sputtering, and venting

Vacuum System

Pumping speed: 133 L/min

Ultimate vacuum: 10⁻⁴ mbar

Noise level: 56 dB

Key Features & Applications

1. Precision and Flexibility

· Adjustable sputtering current (5–30mA) and rotating/tilting stage enable uniform thin-film deposition for diverse sample geometries.

· Dual locking mechanism prevents sample displacement during operation.

2. High-Quality Coating

· Gold (Au) and Platinum (Pt) targets ensure high-purity conductive coatings for SEM and analytical applications.

3. Automated & User-Friendly Operation

· Programmable controls and auto-venting enhance efficiency and safety.

4. Compact & Low-Noise Design

· Stainless steel chamber (120mm × 75mm) with observation window (120mm × 45mm) provides durability and visibility.

· Low 56 dB noise level ensures a comfortable working environment.

Ideal Applications

· SEM sample preparation (conductive coating)

· Thin-film deposition for research and industrial applications

· Multi-sample processing (supports 12 SEM stubs)

· Angle-dependent deposition (with optional rotating/tilting stage)

This sputtering system is optimized for laboratories requiring high precision, automation, and versatile coating capabilities.

|

Parameter |

Specification |

|

Target Materials |

Standard: Au (Gold), 57mm diameter × 0.1mm thick Optional: Pt (Platinum) |

|

Standard Sample Holder |

Holds 12 SEM stubs, height adjustment range: 60mm |

|

Rotating/Tilting Stage (Optional) |

Rotation: 0–60 rpm (continuously adjustable) Tilt: -90° to +90° (continuously adjustable) Standard rotating platform: 40mm diameter (holds 4 sample holders, custom sizes available) Dual locking mechanism for secure fixation |

|

Sputtering Current |

5–30mA (microprocessor-controlled, programmable) |

|

Meters |

Vacuum: Atm – 1×10⁻³ mbar Current: 0–99mA |

|

Control Method |

Microprocessor with Start/Pause buttons Programmable time (1–999s) Auto-pumping, sputtering, and venting |

|

Vacuum System |

Pumping speed: 133 L/min Ultimate vacuum: 10⁻⁴ mbar Noise level: 56 dB |

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported