Wafer Sputtering Coater System For Metal/Dielectric Thin Film Deposition In Semiconductor/Optical

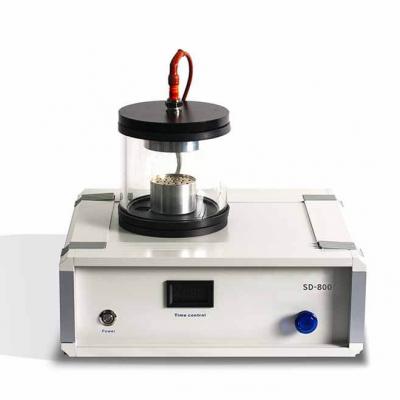

Model: Lith-PD-JS06-Wafer Sputtering Coater System

Product Overview

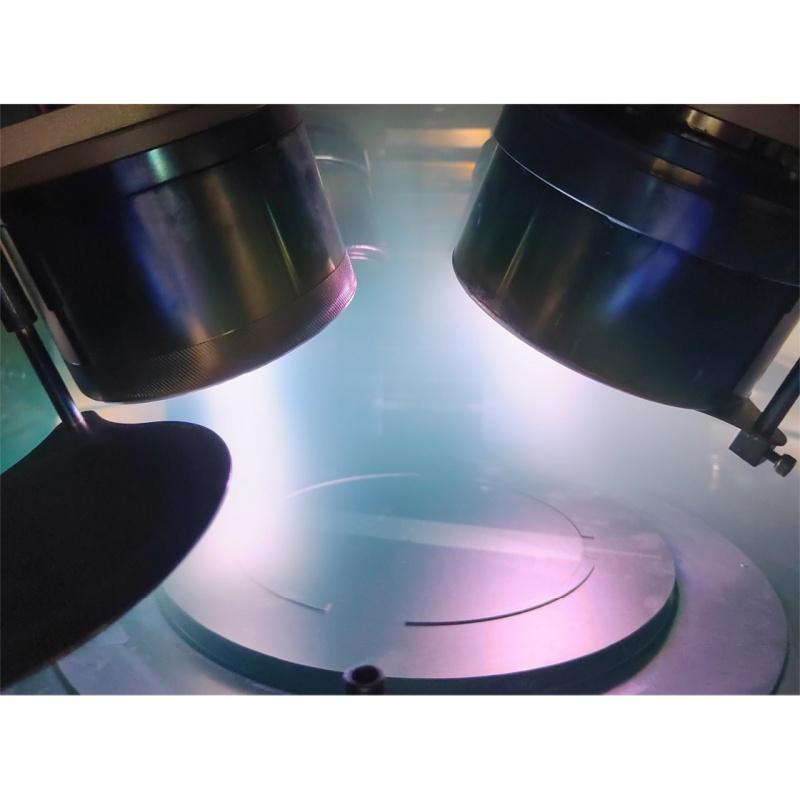

The Lith-PD-JS06 magnetron sputtering system is equipped with multiple sputtering sources, capable of depositing metallic, semiconducting, and dielectric materials. It supports the fabrication of multilayer thin films and co-sputtered alloy films with high precision.

Key Features

· Compact & Integrated Design: Space-saving layout with refined aesthetics, optional sample-loading functionality.

· High Uniformity Coating: Features 4× magnetron sputtering targets (2–4 inches), compatible with 2–8 inch wafers. Substrate holder ensures uniformity within ±3%–5% for 8-inch wafers.

· Flexible Control Options: Siemens PLC + touchscreen (manual/automatic) or PC + PLC full-automatic control.

Technical Specifications

· System Dimensions (L×W×H): 1400 × 1300 × 1900 mm

· Chamber Dimensions (L×W×H): 500 × 500 × 500 mm (PD-500C) / 600 × 600 × 500 mm (PD-600C)

· Substrate Stage: Max heating temperature 500–800°C

· Base Pressure: ≤5 × 10⁻⁵ Pa

· Pumping & Holding: Achieves 8 × 10⁻⁴ Pa within ≤30 min; pressure rise ≤8 Pa over 12 hours.

· Target Configuration: 4× sputter guns (2–3 inches or 2–4 inches), coating area 2–6 inches.

Applications & Advantages

Ideal for R&D and small-batch production, this excels in depositing high-quality, uniform thin films for optics, electronics, and functional coatings. Its modular control and excellent temperature/vacuum stability cater to advanced material research and industrial precision demands.

PD-JS06 vs. Conventional Model

|

Feature |

PD-JS05 |

Conventional Systems |

Advantage |

|

Uniformity (8-inch wafer) |

±3%–5% |

±5%–10% or worse |

Higher film consistency for precision applications |

|

System Footprint |

Compact (1400×1300×1900 mm) |

30–50% larger |

Saves lab/cleanroom space |

|

Substrate Heating |

500–800°C |

Typically 300–600°C |

Supports high-temperature depositions (e.g., oxides, nitrides) |

|

Base Vacuum |

≤5×10⁻⁵ Pa |

~1×10⁻⁴ Pa |

Better for reactive sputtering, reduced contamination |

|

Pressure Stability |

≤8 Pa over 12 hours |

Frequent drift (>10 Pa in hours) |

Longer process stability |

|

Control Options |

PLC + Touchscreen or PC + PLC |

Manual or basic PLC |

Flexible automation, better reproducibility |

|

Target Configuration |

4× guns (2–4 inch) |

Often 2–3 guns (2–3 inch) |

Wider material selection, co-sputtering capability |

|

Coating Area |

2–8 inch wafers |

Typically ≤6 inch |

Broader substrate compatibility |

Key Takeaways

· Precision & Consistency: Superior uniformity (±3–5%) vs. conventional (±5–10%).

· Compact & Efficient: 30% smaller footprint without sacrificing performance.

· High-Temp & Vacuum Stability: Enables advanced materials (e.g., optical coatings, semiconductors).

· Automation Ready: PC-controlled processes improve repeatability over manual systems.

Ideal For: R&D labs, semiconductor fabs, and optical coating producers needing high-repeatability, multi-material deposition in a space-efficient design.

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported