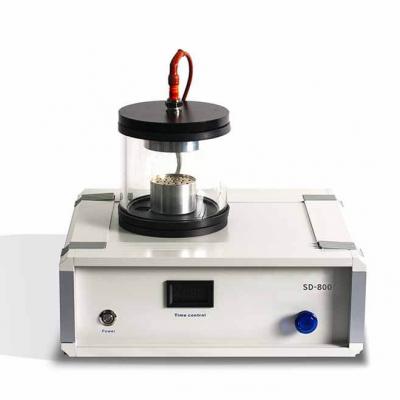

Benchtop Multi-Layer Thermal Evaporator Deposition Coating For Metals, Alloys & Dielectric Film

Lith-ZY-ZD02-Research-Grade Thin Film Deposition Equipment

System Overview

Lith-ZY-ZD02 benchtop resistive thermal evaporation coating system integrates a turbo-molecular pump vacuum assembly to achieve high-vacuum thin film deposition. Equipped with 4 evaporation sources and a precision thickness control system, it is optimized for rapid multi-layer metal/alloy deposition. Featuring a plug-and-play design, this compact instrument operates reliably in office or lab environments without specialized infrastructure, making it ideal for R&D and small-batch production.

Key Advantages

1. Portability & Flexibility

·Compact footprint with multi-environment adaptability (lab/office).

2. User-Centric Design

·One-touch operation with preloaded parameters (100+ metal deposition recipes).

·10" touchscreen for intuitive process control and real-time monitoring.

3. High-Performance Deposition

·4-source simultaneous evaporation (supports 99 layers of metals/alloys/polymers per run).

·Quartz crystal monitoring for nanometer-level thickness accuracy (±3% uniformity).

4.Premium Components

·All-aluminum chamber for efficient heat dissipation.

·Imported turbo-molecular pump (300L/s) ensures ≤6×10−5 Pa ultimate vacuum.

5.Low Maintenance

·Minimal training required; modular design simplifies servicing.

Typical Applications

· Thin-film material research (metals/dielectrics)

· Optical coatings & nanoelectronics

· Thin-film sensors & MEMS devices

· Custom alloy/polymer multilayer structures

Standard Specifications

|

Component |

Details |

|

Chamber |

400×350×360mm (H), CNC-machined aluminum |

|

Vacuum System |

300L/s turbo pump + dual-stage rotary vane pump |

|

Vacuum Measurement |

Full-range gauge (atmosphere to UHV) |

|

Evaporation Sources |

4 independent thermal sources (cross-contamination-free) |

|

Power Supply |

DC power for multi-layer deposition |

|

Thickness Control |

Quartz crystal monitor + manual/auto mode switching |

|

Software |

Network-upgradable with remote parameter adjustment |

Optional:

· Co-evaporation kit for alloys

· 2" substrate heater (400°C max)

· Water-cooled rotating sample stage

Technical Parameters

· Ultimate Vacuum: ≤6×10−5 Pa (after bake-out)

· Leak Rate: ≤5.0×10−9 Pa·L/s

· Deposition Rate: ≥8 nm/min (varies by material)

· Thickness Uniformity: ≤3% (with planetary rotation)

Site Requirements

|

Parameter |

Specification |

|

Dimensions |

600×720×1200mm (H) |

|

Weight |

85 kg |

|

Environment |

23±3°C, <60% RH |

|

Power |

AC 230V, 32A, 50Hz |

|

Cooling Water |

0.2MPa, 15–25°C, ≥8L/min (optional) |

|

Gas Supply |

99.9% N2 (optional for venting) |

Operational Workflow

· Fully automated process: Pre-programmed vacuum pumping, substrate heating, and evaporation.

· Multi-layer capability: Sequential deposition of 4 materials (up to 99 layers) with customizable thickness/time modes.

· Data export: Real-time parameter logging and remote monitoring.

Why Choose?

· Time-saving: Eliminates complex setup with industry-leading uptime.

· Precision: Combines lab-grade vacuum performance with production-level repeatability.

· Scalability: Modular options cater to evolving research needs.

Ideal for academic labs, startups, and industrial R&D requiring rapid prototyping of advanced thin films.

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported