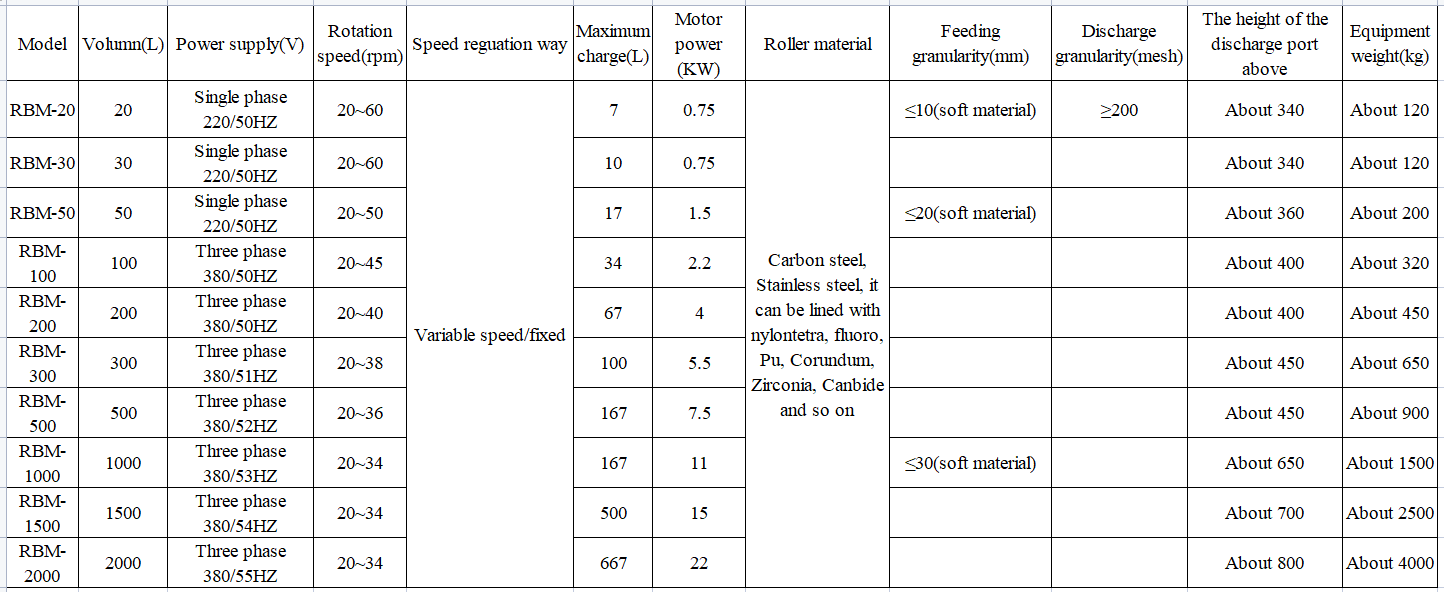

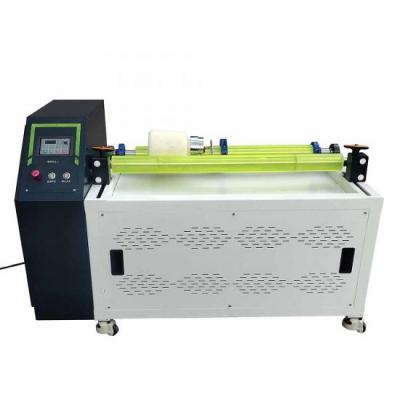

Lab Light Powder Grinder Roller Ball Mill Machine

The grinding medium and the material in the light roller milling tank are lifted to a certain height with the rotation of the cylinder, and fall off the wall of the cylinder due to gravity and fall along the parabola. The material will produce high-energy impact and shear under the impact, rolling and sliding of the grinding medium. Cutting and rolling achieve the technological purposes of crushing, grinding, dispersing, mixing, alloying, spheronization and so on. Multifunctional mixing and grinding machine

Light roller ball mill use

The light roller ball mill is a Chinese-style, ultra-fine grinding equipment for mass production, widely used in electronic materials, magnetic materials, biomedicine, ceramic glaze slurry, metal powder, non-metallic minerals, new materials and other industries.

Features of light drum ball mill

1. The equipment is stable in operation and low in power consumption, suitable for customers with low requirements for material fineness, and is used for Chinese-style and mass production;

2. It can be used for dry and wet grinding, mixing, alloying, spheronization and other processes, and can handle materials with various hardness;

3. The biggest advantage of the equipment is that it can carry out automatic discharging and automatic separation of balls, suitable for mass production, and can be equipped with automatic positioning feeding and discharging systems;

4. According to the different characteristics of customer materials, the ball mill can be lined with liners of different materials, such as: zirconia, alumina, polyurethane, nylon, tetrafluoroethylene, cemented carbide, etc., to ensure that the materials are not polluted and have high purity;

5. Can be customized according to the special needs of customers; ultra-fine mixing mill

Equipment suitable for wet grinding:

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported