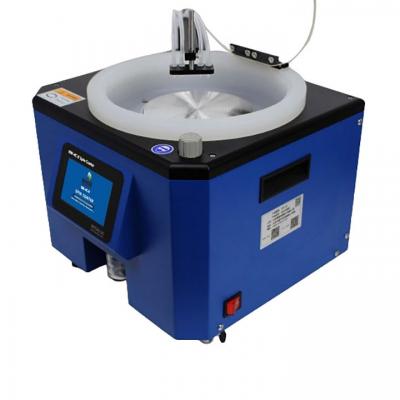

High Speed Spin Coater with PTFE Heating Cover and Ultrasonic Spray

LithC-VTC100PA-PTFEUS is a tabletop spin coater up to 5" diameter at Max. 10000 rpm equipped with a heatable PTFE cover. Two ultrasonic spray nozzles and a heatable glass syringe are included as multiple functions to make liquid atomized or provide a heated solution. The spin head actuator is a precision DC servo motor with accurate speed and acceleration control. The substrate can be held by vacuum (for thinner objects). The device has a user-friendly keyboard and LCD display for programming various parameters up to 12 programs, and 6 segments. Spin duration, spin speed, and acceleration can be programmed from the front panel. All components in the device are corrosion-protected to make it cleanroom compatible.

This spin coaster can be used inside the glovebox with Ar gas (Vacuum pump must be placed outside the glovebox).

SPECIFICATIONS:

Features

|

-

500 ~ 10000 RPM spinning speed programmable

-

PTFE chamber is capable of drying temperatures up to 200°C.

-

Accept substrate from 5 mm to 5"

-

Ultrasonic spray nozzles are included to make liquid-atomized via gravity and low-pressure compressed air.

-

The heatable glass syringe is used to provide a heated solution for spin coating.

-

One gas inlet port on top of the cover for gas filling during the coating.

-

The safety interlock is integrated into the lid.

|

Liquid Injection

|

-

Three liquid injection methods are designed:

-

The ultrasonic spray nozzles are made of Titanium alloy with a power controller for DIY spray pyrolysis. (Pic.1&2)

-

The heatable glass syringe with a digital single-point PID temperature controller up to 120°C (<10 minutes) (Pic.3)

-

A 20ml plastic syringe is included. (Pic.4)

-

Pic.1 Pic.2 Pic.3 Pic.4

|

Coating Chamber

|

-

PTFE chamber for anti-corrosive operation

-

Chamber size: 150 mm diameter

-

Max. Temperature: up to 200°C (<10mins)

-

A set of PTFE vacuum chucks (Ø 40mm and Ø 10mm) are included to hold substrates from 1-inch to 4-inch wafers.

-

About "How to use a vacuum chuck to hold a 10mm square sample", please click the video on the right below.

|

Vacuum Pump

|

|

Programmable Control

|

-

The digital control panel can store 12 programs and each program has 6 segments programmable for speeds, acceleration, and spin duration (please click the picture left to see typical program settings).

-

Speed: 500 rpm - 10000 rpm programmable

-

Duration up to 60 seconds for each segment

-

Acceleration: 100 - 2000 rpm/sec adjustable

-

Accuracy: < 5%

|

Input Power

|

-

AC 220V (Please email us for AC 110V Version)

-

1000 W total for the oilless pump and spin coater

-

24VDC high-speed motor

|

Gas Inlet

|

-

A 6mm diameter gas inlet port on top of the cover allows customers to fill desired gas into the chamber, which can make coating under a variable gas flow environment.

|

Optional

|

-

PE heating cover with a digital single-point PID temperature controller up to 120°C(<10 minutes) is available upon request. The drying process solidifies the as-coated film in less than a few minutes. (Pic.1)

-

UV LED lights and controller with 365 nm wavelength for curing and polymerization are available upon request. (Pic.2)

-

Pic.1 Pic.2

|

|

Application Notes

|

-

To use inside the Ar glovebox, feedthroughs are required to connect the spin coater, the vacuum pump, and the controller, which is optional upon request.

-

To achieve optimal coating quality, please consider cleaning substrates with a plasma cleaner before coating (Pic.2) to significantly reduce the surface tension on the substrates.

-

The OFDP-2 is a tiny silent powerful diaphragm pump, which is made in Germany and provides excellent vacuum performance.

Pic.1 Pic.2

|

|

Compliance

|

-

CE Certified

-

NRTL or CSA certification is available at an extra cost.

|

|

Warnings

|

-

Do not overflush the water bowl/base with any kind of liquid. Excess liquid will leak into the motor shaft and cause damage. Please use a fabric cloth to wipe out the residues in the bow/base.

-

Please turn on the water outlet when flushing the water bowl/base to avoid liquid overflowing during the operation.

-

For more details about the cleaning procedure, please review the "Cleaning Instructions for the Spin Coaters".

|

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

![]()

![]()

![]()

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported