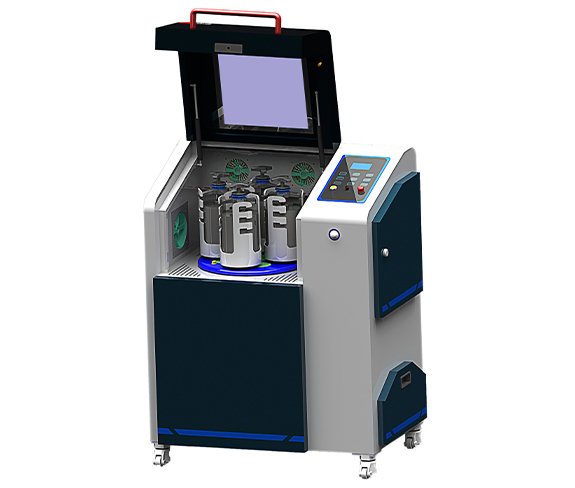

High End Cabinet Planetary Grinding Ball Mill

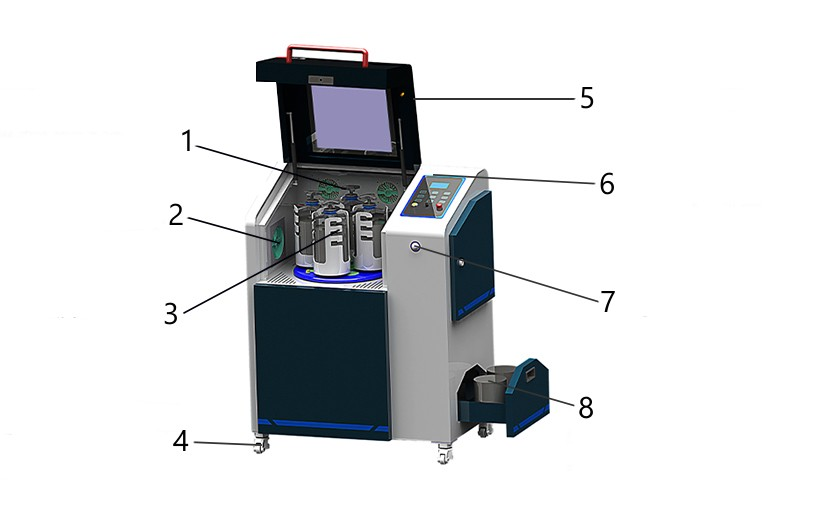

1. Sound-absorbing foam to minimize the noise

2. Good cooling effect of ball mill chamber through internal and external convection circulation system.

3. Three-claw self-locking staring device.

4. High load-bearing universal Foma casters, beautiful, convenient to adjust the level of equipment and handling

5. Safety cover door

6. Pneumatic pole

7. Human body sensor light

8. Pull-out drawer, convenient for storing materials, grinding cans and related tools, etc.

Characteristic

Equipment through the professional appearance design, the shell using high-precision mold stamping, high-precision laser cutting, CNC bending molding, generous and delicate, high-end and stable, planetary disk casting molding, structural components processing using CNC machining process, transmission gear selection of high temperature wear-resistant non-metallic and metal combination of precision gears, nitriding metal heat treatment process, to ensure that rotating parts of the axle wear prevention of broken shafts to ensure that the equipment is stable and quiet when running at high speeds. High-speed operation is smooth and quiet, the grinding canister staring device stares at the grinding canister at the same time can be synchronized with the self-locking anti-loosening, easy to operate, safe and reliable, the shell of the product color matching, give the product new vitality, activate the new life of the product, in line with international and domestic aesthetic demand, in line with ergonomics.

Product performance

|

Transmission mode |

Gear drive |

|

Working method |

Two or four ball milling jars work at the same time |

|

Maximum loading capacity |

Two thirds of the volume of the ball milling jar |

|

Volume of ball milling jar |

Each jar 0.05L-3L, total volume 0.2L-12L. |

|

Feeding granularity |

Soil material ≤10mm, other materials ≤3mm |

|

Discharge size |

Minimum 0.1um |

|

Rotation speed ratio (revolution: rotation) |

See the main parameters of planetary ball mill |

|

Speed (rotation) |

See the main parameters of planetary ball mill |

|

Speed control mode |

Brand frequency converter stepless speed regulation |

1. Modeling design

The shell of the equipment adopts high-precision mold stamping molding, generous and exquisite, high-end and stable, for product color matching, giving the product new vitality, in line with ergonomics.

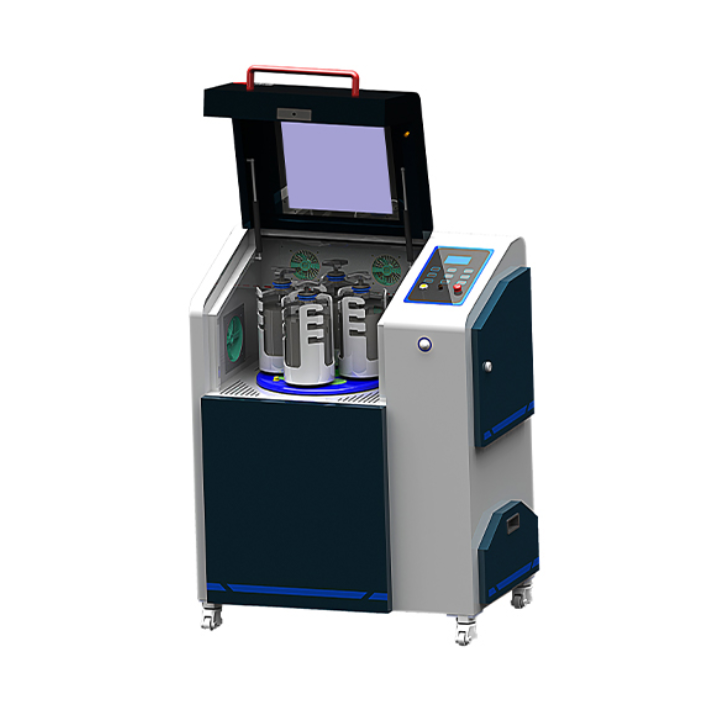

2. Safety electromagnet adsorption door

Equipment door closed electromagnet suction, shutdown manually open the electromagnet disconnect, to prevent the equipment running manually open the cover at the same time to prevent the equipment cavity of foreign objects flying out of the body hurt.

3. Bottom sealing plate protection

The bottom of the equipment is installed with sealing plate and designed with air vent to prevent other materials and belt ash from leaking out and polluting the customer's working environment.

|

Model |

Volume |

Matched jar volume |

Amount |

Matched vacuum jar |

Locking device |

|

PBM-C-1 |

1 |

50-250ml |

4 |

50-100ml |

Self-locking |

|

PBM-C-2 |

2 |

50-500ml |

4 |

50-250ml |

Self-locking |

|

PBM-C-4 |

4 |

250-1000ml |

4 |

50-500ml |

Self-locking |

|

PBM-C-6 |

6 |

1-1.5L |

4 |

50-1000ml |

Self-locking |

|

PBM-C-8 |

8 |

1-2L |

4 |

50-1500ml |

Self-locking |

|

PBM-C-10 |

10 |

1-2.5L |

4 |

50-2000ml |

Self-locking |

|

PBM-C-12 |

12 |

1-3L |

4 |

1-2L |

Self-locking |

|

Model |

Power supply |

Motor power(kW) |

Run the set total time(min) |

Forward and backward alternate running times(min) |

Adjustable speed

|

|

|

Revolution(rpm)

|

Rotation (rpm) |

|||||

|

PBM-C-1 |

220V-50HZ |

0.75 |

1-9999 |

1-999 |

35-370 |

70-740 |

|

PBM-C-2 |

220V-50HZ |

0.75 |

1-9999 |

1-999 |

35-370 |

70-740 |

|

PBM-C-4 |

220V-50HZ |

0.75 |

1-9999 |

1-999 |

35-370 |

70-740 |

|

PBM-C-6 |

220V-50HZ |

0.75 |

1-9999 |

1-999 |

35-370 |

70-740 |

|

PBM-C-8 |

220V-50HZ |

1.5 |

1-9999 |

1-999 |

35-320 |

70-640 |

|

PBM-C-10 |

220V-50HZ |

1.5 |

1-9999 |

1-999 |

35-320 |

70-640 |

|

PBM-C-12 |

220V-50HZ |

1.5 |

1-9999 |

1-999 |

35-320 |

70-640 |

|

Model |

Standard panel (touch screen optional) |

Lubrication mode |

Speed regulation mode |

Weight(kg) |

Dimension L*W*H(mm) |

Noise≤db |

|

PBM-C-1 |

Intelligence |

Grease |

Variable frequency speed regulation |

155 |

870*550*1150 |

55±5 |

|

PBM-C-2 |

Intelligence |

Grease |

156 |

870*550*1150 |

55±5 |

|

|

PBM-C-4 |

Intelligence |

Grease |

157 |

870*550*1150 |

55±5 |

|

|

PBM-C-6 |

Intelligence |

Grease |

158 |

870*550*1150 |

55±5 |

|

|

PBM-C-8 |

Intelligence |

Grease |

175 |

940*620*1200 |

60±5 |

|

|

PBM-C-10 |

Intelligence |

Grease |

178 |

940*620*1200 |

60±5 |

|

|

PBM-C-12 |

Intelligence |

Grease |

180 |

940*620*1200 |

60±5 |

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported