Laboratory Four Jars Full Directional Vertical Planetary Ball

Mill Grinder

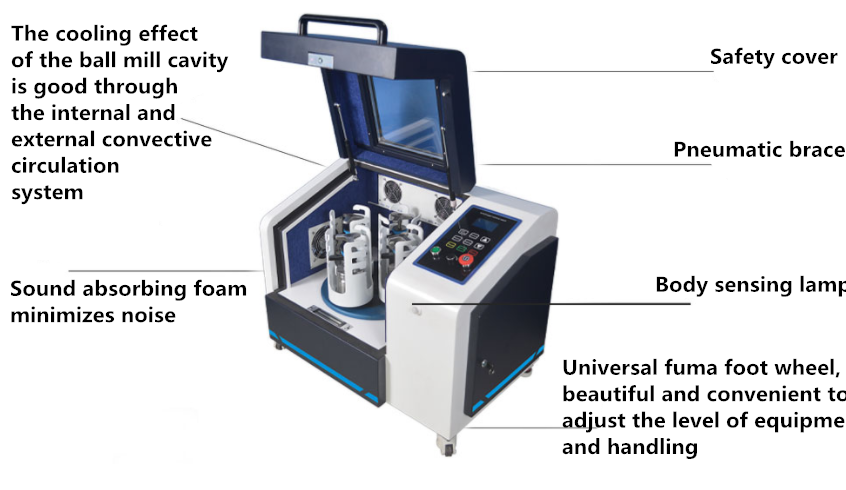

A.Characteristic

Equipment through professional appearance modelling design, the shell is made of high precision mold stamping forming, high precision laser cutting, CNC bending forming, generous and delicate, high-end sedate, planetary disc is made of casting forming, numerical control processing technology on structure component processing, transmission gear combination of high-temperature resistant non-metal and metal precision gear, nitriding metal heat treatment process, Can ensure abrasion resistance to prevent the broken shaft axis of rotation, to ensure smooth and quiet equipment running at a high speed, can watch the device monitor grinding jar can be self-locked locking synchronization at the same time, the operation is convenient, safe and reliable, shell in terms of product color, to bring new energy products, activate the product new life, in line with the international and domestic aesthetic demand, in line with the ergonomics.

B. Parameter

|

Mode of transmission |

Gear transmission |

|

Mode of working |

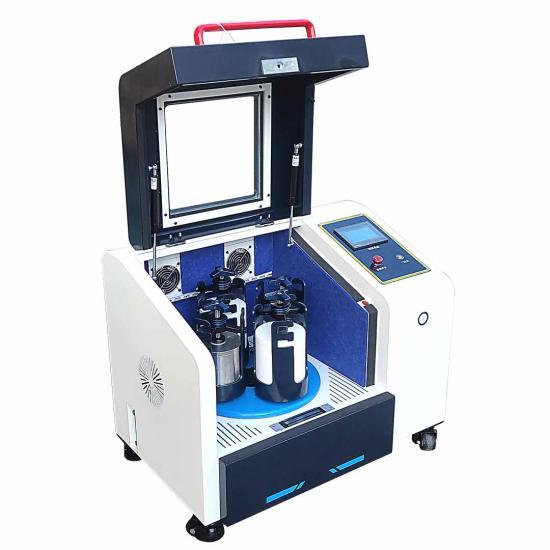

Two and four ball grinding jars work simultaneously |

|

Mode of transmission |

Two thirds of the volume of the ball mill jar |

|

Ball mill tank volume |

0.05-1L per jar, total volume 0.2-4L |

|

Feed granularity |

Soil material≤10mm, and other materials≤3mm |

|

Granularity of discharge |

Up to 1 micron |

|

Mode of speed regulation |

Infinitely adjustable-speed |

|

Model |

Volume(L) |

Configurable ball mill specifications |

Qty |

Configurable vacuum ball jar volume |

Locking device |

|

PBM-1 |

1 |

50-250ml |

4 |

50-100ml |

automatic |

|

PBM-2 |

2 |

50-500ml |

4 |

50-250ml |

automatic |

|

PBM-4 |

4 |

250-1000L |

4 |

50-500ml |

automatic |

|

PBM-6 |

6 |

1-1.5L |

4 |

50-1000ml |

automatic |

|

PBM-8 |

8 |

1-2L |

4 |

50-1500ml |

automatic |

|

PBM-10 |

10 |

1-2.5L |

4 |

50-2000ml |

automatic |

|

PBM-12 |

12 |

1-3L |

4 |

1-2L |

automatic |

|

Model |

Power supply (single-phase) |

Power(kw) |

Total time to run the set(min) |

Alternating positive and negative running time(min) |

Adjustable speed Revolution(rpm) Rotation(rpm) |

|

|

PBM-1 |

Single phase 220V-50HZ |

0.75 |

1-9999 |

1-999 |

35-370 |

70-740 |

|

PBM-2 |

Single phase 220V-50HZ |

0.75 |

1-9999 |

1-999 |

35-370 |

70-740 |

|

PBM-4 |

Single phase 220V-50HZ |

0.75 |

1-9999 |

1-999 |

35-370 |

70-740 |

|

PBM-6 |

Single phase 220V-50HZ |

0.75 |

1-9999 |

1-999 |

35-370 |

70-740 |

|

PBM-8 |

Single phase 220V-50HZ |

1.5 |

1-9999 |

1-999 |

35-320 |

70-640 |

|

PBM-10 |

Single phase 220V-50HZ |

1.5 |

1-9999 |

1-999 |

35-320 |

70-640 |

|

PBM-12 |

Single phase 220V-50HZ |

1.5 |

1-9999 |

1-999 |

35-320 |

70-640 |

|

Model |

Standard panel (optional intelligent, touch screen) |

Lubrication way |

Mode of speed regulation |

Weight(kg) |

Size(Length * width * height) |

Noise≤db |

|

PBM-1 |

intelligent |

grease |

Frequency control |

107 |

870*550*715 |

55±5 |

|

PBM-2 |

intelligent |

grease |

Frequency control |

108 |

870*550*715 |

55±5 |

|

PBM-4 |

intelligent |

grease |

Frequency control |

109 |

870*550*715 |

55±5 |

|

PBM-6 |

intelligent |

grease |

Frequency control |

110 |

870*550*715 |

55±5 |

|

PBM-8 |

intelligent |

grease |

Frequency control |

175 |

940*620*760 |

60±5 |

|

PBM-10 |

intelligent |

grease |

Frequency control |

178 |

940*620*760 |

60±5 |

|

PBM-12 |

intelligent |

grease |

Frequency control |

180 |

940*620*760 |

60±5 |

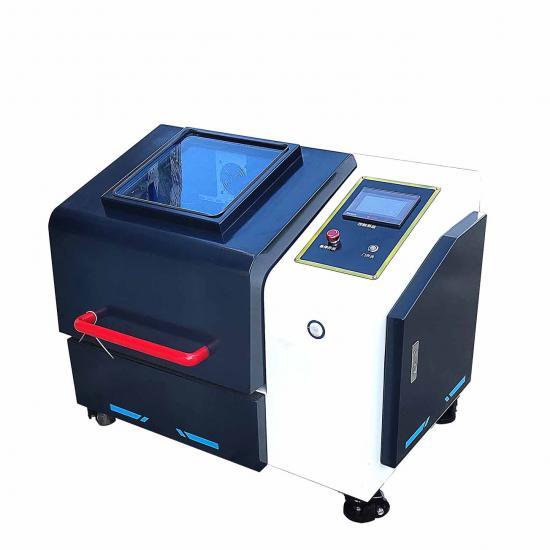

C. Image

1.Modelling design

The equipment adopts high precision die stamping forming, generous and delicate, in line with ergonomics

2. Safety electromagnet adsorption door

When the device door closes, the electromagnet pulls in, and the machine stops, and the electromagnet is opened manually. The electromagnet is disconnected to prevent the device from opening the boot cover artificially during operation, and prevent the foreign body from flying out of the device chamber.

3.The bottom sealing plate

The sealing plate is installed at the bottom of the equipment, and the exhaust outlet is designed to prevent other materials and belt dust from leaking out and polluting the customer's materials.

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported