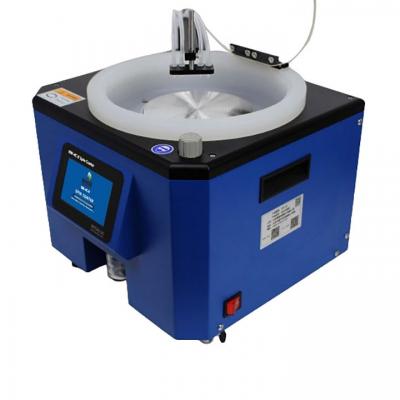

Ar Gas Compatible 6 Inch Wafer Max. Anti Corrosion Spin Coater

LithC-VTC-200P is Anti-Corrosion Spin Coater made of Polypropylene (PP) material, which can be used for active acidic or alkali solution, especially suitable for use inside glovebox under Ar gas. 4'' dia. vacuum chuck is included for coating wafer up to 6". The digital control box is separated from a spin coater which allows you to operate in the remote location. The spinning speed is variable from 500-8000 rpm with six programmable segments. The package includes the oilless vacuum pump and a 20ml syringe for immediate use. This spin coater can be used under Argon atmosphere inside the glovebox

SPECIFICATIONS:

Structure

|

-

Case and spin disk made of Polypropylene (PP) to resist most of the corrosive solutions.

-

The digital control box is separated from the spin coater.

-

One filter is included in the standard package. It is used to connect the pump and coater for preventing wastewater from flowing into the pump.

-

One oil-less vacuum pump is included in the standard package; please click here for specification details.

|

Input Power

|

-

Default 220VAC, 50/60Hz, single phase, 1000W Max.

-

110V is available in optional bar ( with 1500W transformer )

-

A power socket on the back of the Digital control box is used to supply power to the vacuum pump. (The output voltage of this power outlet depends on the input voltage of the spin coater, e.g. if the spin coater is plugged into AC 110V, this power socket will supply AC 110V.)

|

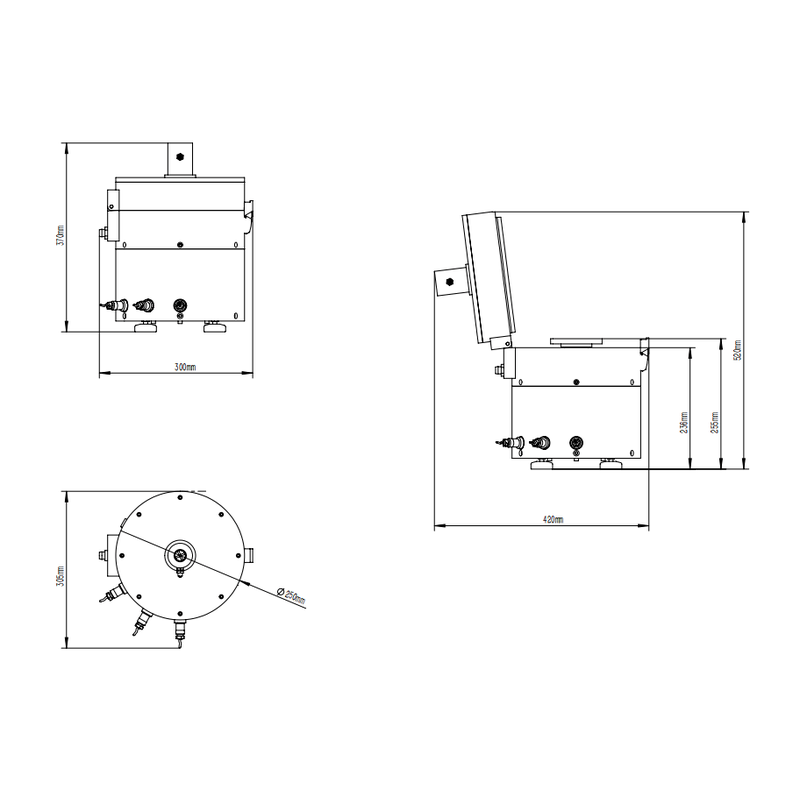

Chamber & Vacuum Chuck

|

-

Chamber diameter: 150 mm

-

The vacuum chuck: Φ100mm, which can hold substrate 4" to 6" Dia. ( Pic. 1)

-

If your sample < 4", please order a small chuck at extra cost ( click Pic. 2 )

-

You may use blue tape for the sample with irregular shape (Pic. 3)

Pic. 1 Pic. 2 Pic. 3

|

|

Vacuum Pump

|

-

One 120L/min Oilless Vacuum Pump is included in the standard package, please click the picture below for specification details. (Pic.1)

-

To put the pump inside Ar glovebox, please use a quiet 24vdc dry pump (Pic. 2 )

-

Pic. 1 Pic. 2

|

Spin Speed

|

-

Digital control panel with six programmable segments of different spin times and speeds

-

Up to 12 Programs/Recipes can be saved and recalled at any time.

-

6 Segments can be set for each program.

-

Max speed ramping/lowering between each segment is 2000 rpm.

-

Maximum programmable spin time 6*60s = 360s

-

500 - 6000 RPM adjustable spinning speedat each segment

-

10000 RPM is available upon request at the extra cost.

-

Special DC motor which can use run under Ar gas and inert gas atmosphere inside a glove box.

|

Liquid Injecting

|

|

Optional

|

-

You may choose Precision Electronic Single Channel Pipette: 20 - 200uL for better coating (Pic. 1 )

-

Using a plasma cleaner to treat the substrate surface before the coating can improve film quality (Pic. 2)

-

You may consider our new product: Heatable syringe (Click Pic 3)

-

Pic.1 Pic.2 Pic.3

-

Heating cover with a digital temperature controller up to 120 is available upon request at extra cost, which allows sample drying in-situ during and after coating (Click Pic 4 & 5). Please confirm 110V or 220V version when you order.

-

Vacuumable spin coater with digital gauge is available ( Pic. 6)

-

If you need to place the coater into a glovebox (Pic. 7), Please let us know in advance. The KF40 feedthrough is needed to connect the power cable of the control box and vacuum pump to the outside glovebox at the extra cost. (Pic.8)

-

Pic.4 Pic.5 Pic.6 Pic.7 pic.8

|

|

Motor

|

24VDC, Brushless, 200W max.:

|

|

Net Weight

|

25 kg

|

|

Compliance

|

|

Application Notes

|

-

Please clicks here to review an article on "Spin Coater Theory and Processing."

-

To achieve better coating quality, please consider cleaning substrates by plasma cleaner before coating

-

The OFDP-2 is a tiny silent powerful diaphragm pump made in Germany and provides an excellent vacuum performance; now it's only $1455 for you to have this pump.

-

You may consider placing the spin coater into a small glovebox and coat under an inert gas atmosphere

-

Cleaning instruction for the spin coaters.

-

-

There is a 12-second delay time before and after the spin-coating to assure the vacuum is applied before spinning and the sample stage is fully stopped after spinning.

|

|

Warnings

|

-

Do not over flush the water bowl/base with any kind of liquid. Excess liquid will leak into the motor shaft and cause damage. Please use fabric cloth to wipe out the residues remain in the bow/base.

-

If necessary, turn on the water outlet when flushing the water bowl/base to avoid liquid overflowing during the operation.

-

For the cleaning procedure, please review the cleaning instruction for the spin coaters.

|

STANDARD PACKAGE:

|

Item #

|

Description

|

Qty

|

|

1

|

LithC-VTC-200P Desktop Spin Coater

|

1

|

|

2

|

Digital control box

|

1

|

|

3

|

4" ( 100mm) Vacuum Chuck

|

1

|

|

4

|

20mL Syringe for dropping coating solvent on the plate

|

1

|

|

5

|

500mm Hose for connecting a vacuum pump

|

2

|

|

6

|

Filter (connect to vacuum pipe to keep water from flowing into the pump)

|

1

|

|

7

|

Oil-less vacuum pump

|

1

|

|

8

|

Blue Adhesive Tape (6" W x 24" L)

|

1

|

|

9

|

Spin disk wrench

|

1

|

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

![]()

![]()

![]()

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported