Lab Vertical Planetary Ball Miller Machine with Intelligent Panel

Introduction

Vertical manufacturing planetary ball mill was conducted based on the principles of small planetary ball mill amplification of large planetary ball mill design, manufacture, production planetary ball mill is mainly suitable for large users, Chinese batch grinding, mixing, alloying and production, is widely used in geology, mining, metallurgy, electronics, building materials, ceramics, chemical industry, light industry, medicine, cosmetic, environmental protection, etc.

Features

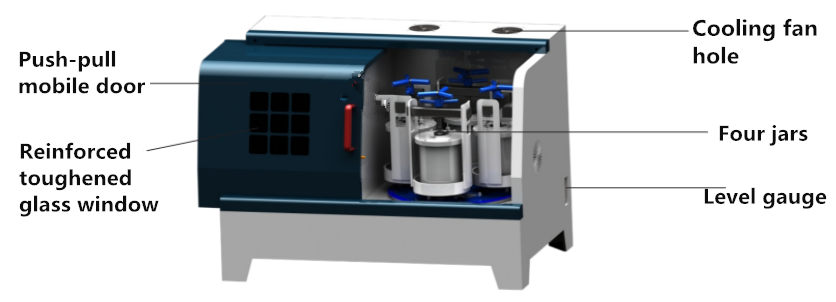

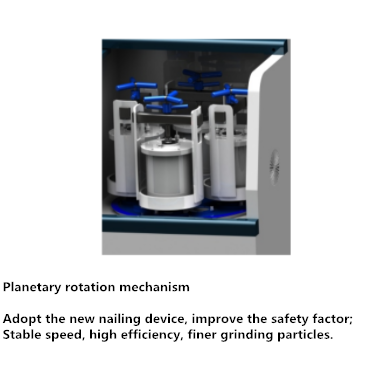

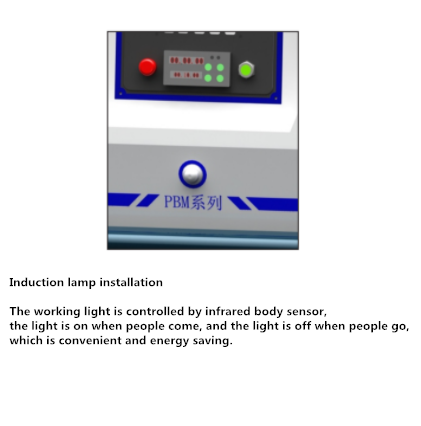

Equipment through professional appearance design, shell using high-precision laser cutting, numerical control bending molding, generous and delicate, high-end stable, planetary disk using one-body molding, structural components using numerical control processing technology processing,The nitriding metal heat treatment process ensures the wear-resisting of the rotating shaft and prevents the shaft from breaking. The transmission gear adopts high-temperature wear-resisting non-metal and metal combination precision gear. The lubricating oil foaming gear box type self-lubrication is adopted to achieve good heat dissipation and the liquid oil level meter is equipped for easy replacement to ensure the stable and quiet operation of the equipment at high speed.Can watch the device monitor grinding jar can be self-locked locking synchronization at the same time, the operation is convenient, safe and reliable, equipment can monitor temperature instrument ball mill cavity in the body temperature, easy configuration level heavy equipment installation, lifting and pouring device adopts integrated design, both separated with vibrating screen device design agencies, simplicity of operation, implement quick easy take cans, unloading and loadingTank, reduce labor intensity, improve production efficiency.The shell matches the color of the product, gives the product new vitality, activates the new life of the product, conforms to the international and domestic aesthetic needs, and conforms to the ergonomics.

|

Product Performance |

|

|

Drive mode |

Gear drive |

|

Working mode |

Two jars and four jars working at the same time |

|

Maximum sample size |

Two thirds of the volume of the ball mill jar |

|

Jar volume |

5L-25L, total volume of 20 L- 100 L |

|

Feeding granularity |

Soil material ≤ 10 mm, other materials ≤ 3 mm |

|

Discharge material size |

Min 0.1um |

|

Speed ratio

(revolution: rotation) |

1:2 |

|

Rotating speed |

Revolution 335r / min,

Rotation 670r / min |

|

Speed mode |

Infinitely adjustable-speed |

|

Vertical production type planetary ball mill(1) |

|||||

|

Model |

Specification |

Volume of configurable ball mill jar |

NO. |

Volume of vacuum ball mill jar |

Locking method |

|

PBM-20 |

20 |

2-5L |

4 |

2-4L |

Self-locking |

|

PBM-40 |

40 |

5-15L |

4 |

5L |

Self-locking |

|

PBM-60 |

60 |

10-15L |

4 |

10L |

Self-locking |

|

PBM-80 |

80 |

15-20L |

4 |

15L |

Self-locking |

|

PBM-80 |

100 |

20-25 |

4 |

20L |

Self-locking |

|

Vertical production type planetary ball mill(2) |

|

|||||

|

Model |

Input power |

Power |

Operating time setting

(min) |

Positive and negative alternating operation time(min) |

Adjustable speed

Revolution

(rpm) |

Adjustable speed

Rotation

(rpm) |

|

PBM-20 |

Three-phase 380 v - 50 hz |

4 |

1-9999 |

1-999 |

25-215 |

50-430 |

|

PBM-40 |

Three-phase 380 v - 50 hz |

5.5 |

1-9999 |

1-999 |

20-195 |

40-390 |

|

PBM-60 |

Three-phase 380 v - 50 hz |

7.5 |

1-9999 |

1-999 |

27-174 |

40-260 |

|

PBM-80 |

Three-phase 380 v - 50 hz |

11 |

1-9999 |

1-999 |

27-160 |

40-240 |

|

PBM-100 |

Three-phase 380 v - 50 hz |

11 |

1-9999 |

1-999 |

27-160 |

40-240 |

|

Vertical production type planetary ball mill(3) |

||||||

|

Model |

Standard panel(Optional touch-screen version) |

Lubrication way |

Speed adjustment mode |

Equipment reference weight |

Equipment reference size |

Noise

≤db |

|

PBM-20 |

Intelligent lubrication |

Frequency control |

440 |

1300*810*950 |

60db |

|

|

PBM-40 |

Intelligent lubrication |

Frequency control |

680 |

1500*850*1050 |

60db |

|

|

PBM-60 |

Intelligent lubrication |

Frequency control |

880 |

1700*950*1150 |

60db |

|

|

PBM-80 |

Intelligent lubrication |

Frequency control |

1100 |

1850*1100*1200 |

60db |

|

|

PBM-100 |

Intelligent lubrication |

Frequency control |

1100 |

1850*1100*1200 |

60db |

|

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported