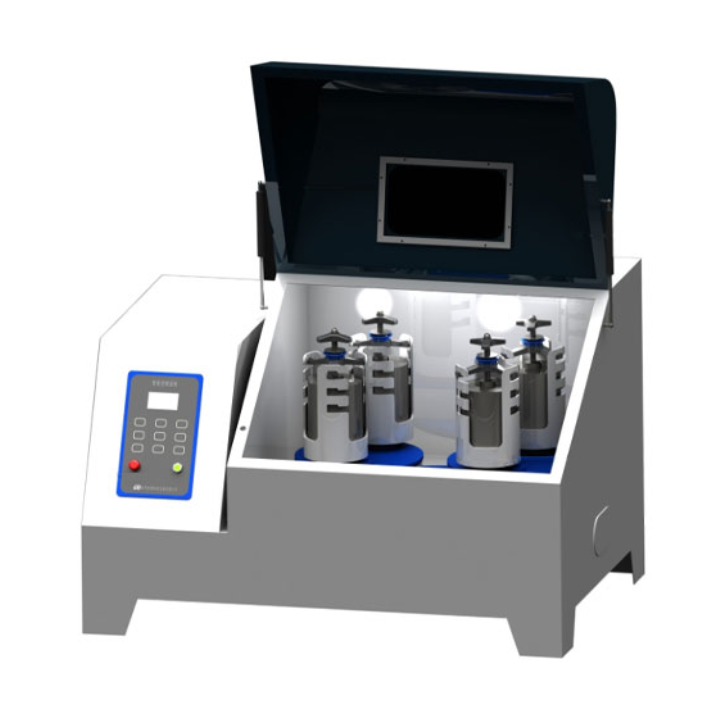

Lab Super Fine Grinding Double Planetary Ball Mill

Intelligent panel control

Personnel fool operation, more convenient, simple, glass touch panel more grade.

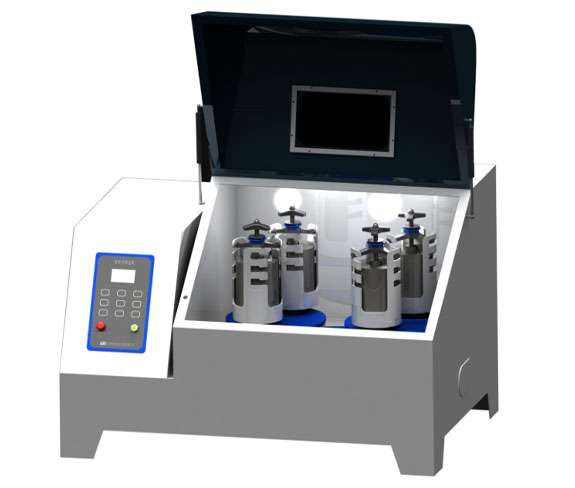

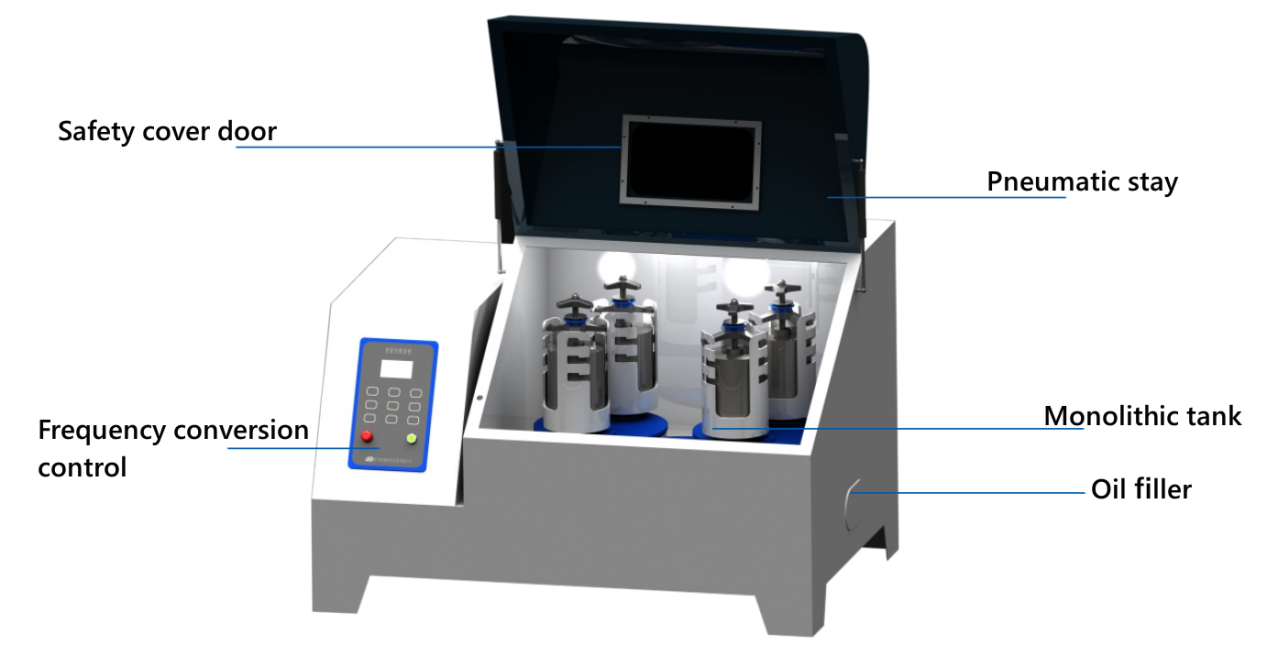

Safety cover door

Protect the inside of the ball mill.

Cooling fan hole

High-speed operation, effectively enhance the body air flow speed, heat dissipation speed to ensure the effective long-term stable operation of the machine.

Planetary mechanism

The whole forming main plate, the use of new pressure rod, elegant and beautiful; Stable speed, high efficiency, finer grinding particles.

Introduction

Double planetary structure to realize the large planetary disk drives the small planetary disk movement, the radius of rotation and the rotation speed of the grinding jar compared with the ordinary planetary ball mill with the same specifications has been enlarged, the centrifugal force on the grinding balls increases exponentially, and the collision, shear, friction between the grinding balls increases significantly, which improves the grinding effect and grinding efficiency, and part of the material can be milled to nanometer level. Double planetary ball mill is a typical high-efficiency, high-energy ball mill.

Features

Equipment shell professional appearance design and industrial modeling, the use of thickened steel plate welding molding process, high strength, impact resistance, deformation resistance, atmospheric stability; mechanical parts of the strict heat treatment process, the use of CNC machining process, the transmission gear selection of special materials and precision gears to ensure that the equipment running at high speeds, stable, safe, low noise.

Product performance

|

Transmission mode |

Gear drive |

|

Working method |

Two or four ball milling jars work at the same time |

|

Maximum loading capacity |

Two thirds of the volume of the ball milling jar |

|

Volume of ball milling jar |

Each jar 0.05L-1.5L, total volume 0.2L-6L. |

|

Feeding granularity |

Soil material ≤10mm, other materials ≤3mm |

|

Discharge size |

Minimum 0.1um |

|

Rotation speed ratio (revolution: rotation) |

See the main parameters of planetary ball mill |

|

Speed (rotation) |

See the main parameters of planetary ball mill |

|

Speed control mode |

Brand frequency converter stepless speed regulation |

Product features

1. Equipment shell

Professional appearance design and industrial modeling, the use of thickened steel plate welding molding processing technology, high strength, impact resistance, anti-deformation atmosphere stable, to ensure the consistency and repeatability of the test.

2. Machined parts

The material is strictly heat-treated process, using CNC machining process.

3. Transmission gear

Precision gears made of special materials are selected to ensure smooth, safe and low noise when the equipment is running at high speed.

|

Model |

Volume |

Matched jar volume |

Amount |

Matched jar |

Locking device |

|

DPBM-0.4 |

0.4L |

50-100ml |

4 |

50ml vacuum ball milling jars |

Self-locking |

|

DPBM-1 |

1L |

50-250ml |

4 |

50-100ml vacuum ball milling jars |

Self-locking |

|

DPBM-2 |

2L |

50-500ml |

4 |

50-250ml vacuum ball milling jars |

Self-locking |

|

DPBM-4 |

4L |

250-1000ml |

4 |

50-500ml vacuum ball milling jars |

Self-locking |

|

DPBM-6 |

6L |

1-1.5L |

4 |

50-1000ml vacuum ball milling jars |

Self-locking |

|

Model |

Power supply |

Motor power(kW) |

Run the set total time(min) |

Forward and backward alternate running times(min) |

Adjustable speed

|

|

|

Revolution(rpm)

|

Rotation (rpm) |

|||||

|

DPBM-0.4 |

Single phase 220V-50HZ |

1.5 |

1-9999 |

1-999 |

70-560 |

140-1120 |

|

DPBM-1 |

1.5 |

1-9999 |

1-999 |

70-560 |

140-1120 |

|

|

DPBM-2 |

1.5 |

1-9999 |

1-999 |

70-560 |

140-1120 |

|

|

DPBM-4 |

1.5 |

1-9999 |

1-999 |

70-560 |

140-1120 |

|

|

DPBM-6 |

1.5 |

1-9999 |

1-999 |

70-560 |

140-1120 |

|

|

Model |

Standard panel (touch screen optional) |

Lubrication mode |

Speed regulation mode |

Weight(kg) |

Dimension L*W*H(mm) |

Noise≤db |

|

DPBM-0.4 |

Intelligence |

Grease |

Variable frequency speed regulation |

245 |

920*660*640 |

65±5 |

|

DPBM-1 |

Intelligence |

Grease |

245 |

920*660*640 |

65±5 |

|

|

DPBM-2 |

Intelligence |

Grease |

245 |

920*660*640 |

65±5 |

|

|

DPBM-4 |

Intelligence |

Grease |

245 |

920*660*640 |

65±5 |

|

|

DPBM-6 |

Intelligence |

Grease |

245 |

920*660*640 |

65±5 |

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported