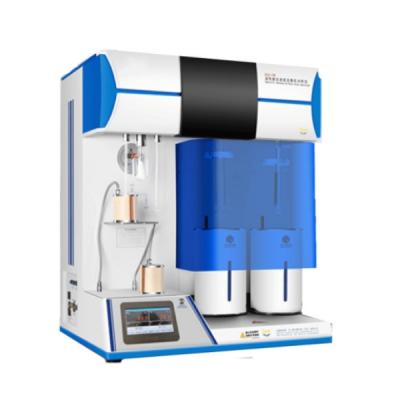

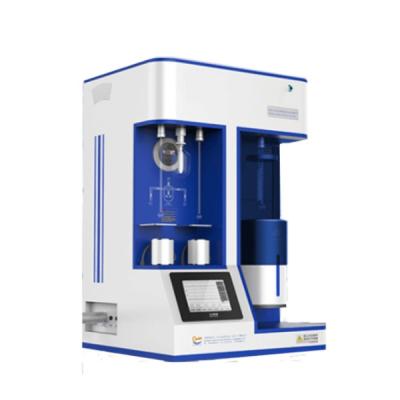

Lab Eight Stations Purge Degassing Preprocessing System

Product overview:

a. Processing digits: 8 processing digits, divided into 2 groups*4 processing digits; 2 groups of processing digits can work independently without affecting each other;

b. Cooling position: 8 cooling positions, the sample tube after high temperature treatment can be moved to the cooling position to return to normal temperature and then disassembled;

c. Automatic timing: different processing temperature and processing time can be set;

d. Purging temperature: room temperature ~ 400 ℃, temperature control accuracy ± 1 ℃;

Product introduction:

For the dynamic chromatography rapid specific surface instrument, in order to obtain the real specific surface result of the material, the sample needs to be pretreated by heating and purging before the test. The automatic rapid specific surface analyzer for dynamic chromatography independently developed and produced by Bester has the function of in-situ heating pretreatment. After the sample loading is completed, it is only necessary to install the sample tube in the test position, perform heating pretreatment first, and then directly test it. There is no need to disassemble and transfer the sample tube during the process.

However, in the case of heavy testing tasks, in-situ processing will cause the test position of the instrument to be occupied, resulting in a decrease in the utilization rate of the test position. Therefore, Best launched the BSD-AD8 purging pretreatment machine. The sample can be purged on the pretreatment machine first, and then transferred to the instrument for testing, which increases the testing efficiency by more than 2 times.

Performance Parameter:

a. Supporting instruments: 3H-2000A, 3H-2000BET-S, 3H-2000BET-A automatic specific surface analyzer;

b. Processing digits: 8 processing digits, divided into 2 groups*4 processing digits; 2 groups of processing digits can work independently without affecting each other;

c. Cooling position: 8 cooling positions, the sample tube after high temperature treatment can be moved to the cooling position to return to normal temperature and then disassembled;

d. Automatic timing: different processing temperature and processing time can be set;

e. Purging temperature: room temperature ~ 400 ℃, temperature control accuracy ± 1 ℃;

f. Purge gas flow: 2 channels*80ml/min;

g. Touch screen temperature control: touch-type large-screen temperature controller makes temperature control more accurate and the heating process is visualized;

h. Quick disassembly and assembly: the sample tube is sealed by quick insertion, and the operation is simple and convenient;

i. Specification: L435*W390*H470; Weight: 25kg; Power: 600W;

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported