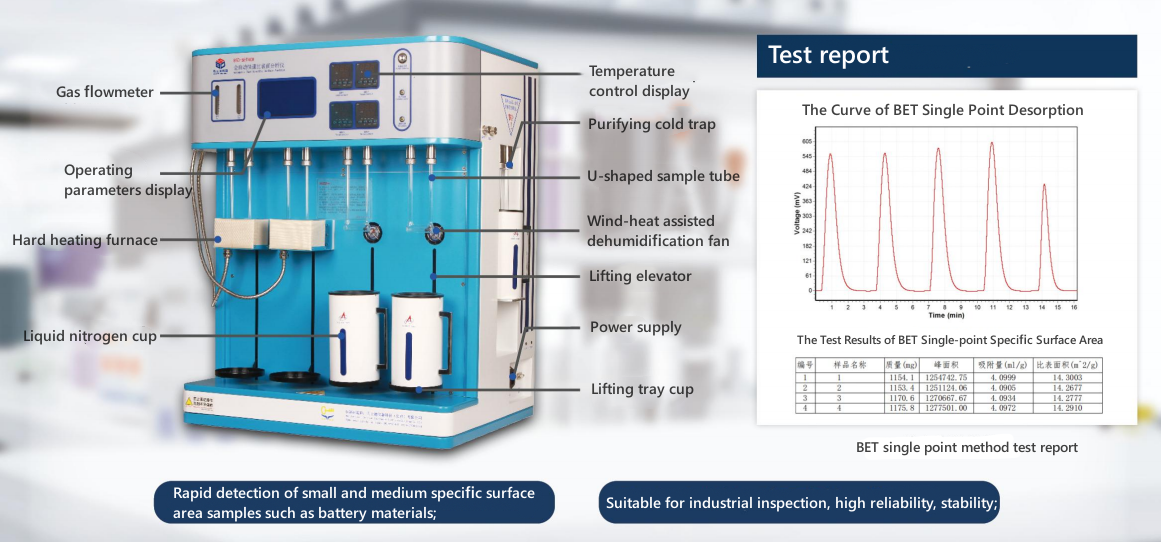

Auto Nitrogen Adsorption Specific Surface Area Analyzer with Gas Purification Cold Trap

Performance parameters

◆ Test method: solid specimen reference method (particle size estimation).

◆ Test accuracy: high test accuracy and good reproducibility. Test relative error is less than ±1.5%.

◆ Test range: wide test range, can determine the specific surface area in the range of 0.0005m²/g or more substances, to meet all powder substances and porous material specific surface area testing;

◆ Sample type: powder, particle, fiber and flake materials, etc;

◆ Test time: 3 samples can be tested at the same time by the solid sample reference method, and the average measurement time for each sample is about 6 minutes, and the above test time does not include the sample pretreatment time. The above test time does not include the sample pre-treatment time. Because of the patented wind-heat-assisted stripping technology, it can greatly improve the test efficiency;

◆ Test gas path: low temperature nitrogen adsorption dynamic chromatography method, unique parallel gas path at home and abroad, eliminating the ambient temperature, humidity, atmospheric pressure and other external influences, no need to pump vacuum, the laboratory conditions are relatively relaxed;

Advantages

◆ Wind-heat assisted detachment: with program-controlled wind-heat assisted detachment device, to ensure that a sharp and rapid detachment peak, reduce background errors to improve test efficiency and accuracy;

(Role: reduce background noise and improve sensitivity)

◆ Blowing treatment: with an integrated degassing device (non-split), to achieve in-situ processing of the sample, zero contact with air, to ensure the efficiency of sample pretreatment, and effectively improve the test accuracy; (Role: improve pretreatment efficiency)

◆ Chromatographic detection: with chromatographic method of nitrogen partial pressure detection system, relative to the flow method accuracy increased by 10 times, so that the nitrogen concentration control accuracy and detection accuracy are up to one ten thousandth, high stability; (Role: improve the accuracy of partial pressure detection)

◆ Purification cold trap: with gas purification cold trap, so that the gas purity increased by more than 1 order of magnitude; (Role: reduce the impact of impurities in the gas)

◆ Zero drift suppression: with detector thermostat system, so that the detector 10min drift is less than 0.1mV, to ensure the accuracy and stability of test results;

(Role: suppress zero drift)

◆ Sample tube: ensure the accuracy of the test while making the sample tube easy to load and not limited to powder sample testing; (Role: large inlet and small outlet, convenient to load samples)

◆ Timing of blowing: with blowing timing function, timing accuracy 1 second. Automatically cut off the heating power after the completion of the countdown, and sound prompt;

◆ Nitrogen partial pressure: program-controlled servo partial pressure adjustment system, nitrogen partial pressure control runs automatically throughout;

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported