Lab Automatical True Density and Porosity Analyzer

Parameter

BSD-TD

BSD-TD-K

BSD-TD-Y

BSD-TD-S

Sample type

Powder, bulk solid, slurry, liquid

Foaming material

Rock core, plastic, nylon ceramic, etc.

Petroleum products such as crude oil, lubricants, product oils and other liquids

Test content

True density

True density, open porosity, closed porosity

True density, porosity

True density

National standard

GB/T 23561.2-2009

GB/T10799-2008

ASTMD6226-2005, ISO4590: 2002

GB/T23561.2-2009

GB/T 1885-1998

It can test the apparent density of crude oil, product oil and lubricating oil at any temperature and convert it to the standard density at 20 degrees

Test accuracy

Standard aluminum column accuracy is better than ±0.03%, standard aluminum column repeatability is better than ±0.015%, resolution: 0.0001g/ml

Test speed

It takes 1-2 minutes to complete a test process (excluding constant temperature time), and double-station analysis efficiency is doubled. The program automatically tests 6 times continuously and takes the average value.

Constant temperature mode

Fully automatic programmed constant temperature mode,programmed control of the constant temperature process, and automatically enter the test process. This constant temperature mode is optional;

Sample cell

10ml;

Cylinder

16* 54.5mm

30ml;

Inner square sample cell:

25*25*50mm

10ml or 30ml

pick one of two

10ml;

Cylinder

16* 54.5mm

There is also a micro-volume sample cell with a maximum volume of 3ml for micro-sample; it can also be easily expanded to 2000ml (with a corresponding large-volume expansion chamber with automatic switching); various specifications of sample cells can be customized for special requirements

Product features and advantages

a. Fully automated: One-click completion of gas path flushing, sample flushing, system constant temperature, repeated tests, and results are given.

b. BSD-TD-K: Sample cell: It has a special porosity sample cell specially designed for foaming materials, made of stainless steel, with a cubic space inside, which can make the utilization rate of the sample cell reach more than 80% (the national standard requires more than 15%) , much higher than that of ordinary cylindrical sample cells.

(Patent Name: True Density and Porosity Analyzer with Internal Sample Cell Patent No.: 201420149458.9)

c. Test method: The "bottom-loading" test method that uses sample pools of different volumes directly as the sample test chamber is adopted. Compared with similar instruments that change the volume of the test chamber by filling, it has a high utilization rate of the volume of the sample test chamber. Advantages, so that the test accuracy can be improved; the "bottom-mounted bayonet type" sample cell can conveniently meet the needs of micro-volume and large-volume sample loading at the same time, so as to achieve the purpose of improving test accuracy.

(Patent Name: Sample Cell Bottom-loading True Density Meter Patent No.: 201120436207.5)

d. Constant temperature mode (optional): Fully automatic programmed constant temperature mode; programmed control of the constant temperature process, and automatically enter the test process.

(Patent name: gas displacement method true density meter and its gas source pre-thermostatic tube patent number: 201220708191.3)

e. Valve type: air-operated valve, which fundamentally eliminates the temperature change and temperature inhomogeneity of the reference chamber caused by the heating of the electromagnetic valve structure of similar instruments, ensuring the ideal constant temperature effect; it fundamentally subverts the use of software The correction method is used to reduce the error caused by the electromagnetic valve heating and destroying the constant temperature effect.

(Patent Name: Pneumatic Control Valve True Density Meter Patent No.: 201220140709.8)

f. Standard sample: Each instrument is equipped with a standard aluminum column sample, which has been tested by a national authority and has a corresponding test certificate.

g. Reference cavity: There is a built-in reference cavity; (extension cavity is optional, and the expansion cavity can improve the test accuracy for different sample cell volumes; the program automatically selects whether to enable the expansion cavity according to the sample cell volume).

h. Air circuit: Modular air circuit structure, no pipe joints between valves, reducing air leakage points, and uniform temperature field.

i. Pressure balance: It has three modes of pressure balance time: automatic default, user selection and user-defined, adapting to samples of different structures.

j. Self-inspection process: Advanced intelligent self-inspection process, intelligently judge whether there is air leakage in the sample pool and whether the airtightness of the instrument is qualified, and completely solve human error.

k. Detection and measurement: The instrument has passed the measurement certification of Beijing Institute of Metrology and Testing Sciences and has a test certificate.

l. Return to normal pressure: It has the function of automatically returning to normal pressure after the test to prevent the sample from splashing.

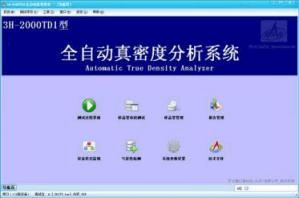

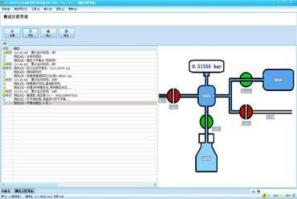

m. Control interface: Clear and vivid graphical control interface, and all hardware control operations can be performed on the interface.

n. Operation log: Detailed instrument operation log, the time is accurate to the second, which provides guarantee for the reliable operation and after-sales of the instrument.

Technology Introduction

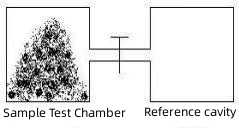

1. Test principle

Apply the Archimedes principle - gas expansion displacement method, use the Bohr's law (PV=nRT) of inert gas with small molecular diameter under certain conditions, and accurately measure the sample by measuring the volume of gas displaced by the sample in the test chamber skeletal volume (including closed cells), so as to obtain its true density, true density=mass/skeleton volume.

The gas expansion displacement method uses gas to replace liquid to measure the volume displaced by a sample. This method can avoid the test error caused by the dissolution of the sample in the immersion method, and has the advantage of not damaging the sample. Because the gas can penetrate into the extremely small pores in the sample and the irregular pores on the surface, the measured sample volume is closer to the skeleton volume of the sample, which can be used to calculate the density of the sample, and the measured value is also closer to the real density of the sample.

The test system of the instrument consists of a test cavity and a reference cavity, as shown in the figure.

Sample mass to be tested: M; Test cavity volume: V1; Reference cavity volume: V2;

When determining the true density of a sample:

1. Put a sample with a skeleton volume V (to be tested) into the test chamber;

2. The instrument automatically opens the test valve and exhaust valve to empty the gas in the test chamber and the reference chamber, closes the exhaust valve, and when the pressure is stable, record the pressure P1 at this time;

3. Close the test valve, inject a certain amount of gas into the reference chamber and record the stable pressure P2;

4. Open the test valve, connect the sample test chamber to the reference chamber and record the stabilized pressure P3; before and after opening the test valve, the total molar amount of gas in the test chamber and the reference chamber is equal, so it can be seen that:

P1 (V1-V)+P2V2=P3 [(V1-V)+V2],

That is, V=V1- (P2-P3)V2/(P3-P1),

ρ=M/V

That is: the skeleton volume and true density of the material can be obtained.

2. Comparison of gas displacement method and immersion method

The gas expansion displacement method uses gas to replace liquid to measure the volume displaced by the sample. This method eliminates the possibility of sample dissolution by the immersion method, and has the advantage of not damaging the sample. Because the gas can penetrate into the tiny pores in the sample and the irregular cavities on the surface, the measured sample volume is closer to the skeleton volume of the sample, which can be used to calculate the density of the sample, and the measured value is also closer to the real density of the sample. In addition, it has higher test efficiency and automation.

3. The significance and method of cutting hole correction of foam materials

For the open-cell and closed-cell rate tests of materials such as foam, during the preparation of cuboid samples, when cutting the 6 surfaces of the sample, some closed-cell foams will always be artificially cut into open-cell cells. Therefore, the measured apparent closed (open) ratio must be corrected to obtain the corrected closed (open) pore volume fraction, in order to faithfully characterize the cell structure of the sample and correctly evaluate the performance of the sample.

The correction is based on the "8-point method" described in "Appendix B (Normative Appendix) Correction of Opening Errors in Sample Preparation" in the national standard GB/T10799-2008.

4. The difference between the air control valve and the solenoid valve in the application of the true density meter

The air-operated valve is driven by the gas cylinder to drive the valve core to realize the closing and opening of the valve, so there is no heat generation and the valve temperature is stable.

The solenoid valve drives the spool action by the magnetic field generated by the current to realize the closing and opening of the valve. The solenoid coil generates heat, and the temperature of the valve increases with the increase of the electrification time; The error of 0.3% is far greater than the repeatability error requirement of 0.02%. Therefore, for occasions that require high temperature stability, it is necessary to use a zero-heat air control valve instead of a solenoid valve to improve the stability of the system temperature; however, the driving gas of the air control valve needs to be controlled by the solenoid valve to supply or cut off, which is relatively simple. Direct use of solenoid valves will increase hardware costs. The key point of the true density test is the accurate quantification of the gas volume, so as to obtain the accurate volume of the sample, which has high requirements for constant temperature.

BSD-TD series automatic true density meter adopts the most advanced air control valve control structure in the industry, which fundamentally eliminates the volume quantitative error caused by the solenoid valve heating caused by the solenoid valve used in similar instruments.

(Patent Name: Pneumatic Control Valve True Density Meter; Patent No.: 201220140709.8)

5. About the "bottom-loading" sample cell installation method

The BSD-TD series full-automatic true density meter has the advantage of high utilization rate of the volume of the sample test chamber due to the advanced "bottom-loading bayonet type" sample cell installation method, which uses the sample cell directly as the sample test chamber; for 10ml samples Pool, the volume utilization rate of the test chamber is higher than 90%, which improves the test accuracy for a small amount of samples. However, the usual sample cell is "top-mounted and covered", and the sample cell is put into the test barrel and sealed with a cover for testing. The sample test chamber composed of "test barrel + sample cell" has a large amount of remaining useless space, making the test chamber The volume utilization rate is low. For a 10ml sample pool, the volume utilization of the test chamber is less than 10%, which makes it difficult to guarantee the test accuracy for a small amount of samples.

On the other hand, the volume of the "top loading and capping" sample cell is limited by the volume of the capped test barrel, which is not suitable for large-volume sample loading (it is difficult to meet the sample loading volume of 150ml or more), while the "bottom loading bayonet type" "The sample cell can meet the needs of large-volume sample loading, so that the upper limit of sample loading can reach more than 500ml, so as to achieve the purpose of broadening the test range, expanding the application area, and improving the test accuracy.

(Patent name: True Density Meter with Bottom Loading Sample Cell; Patent No.: 201120436207.5)

6. What is an expansion chamber and what is its function?

When the difference between the volume of the test cavity and the volume of the reference cavity is too large, it is not conducive to the improvement of the test accuracy; and the volume of the test cavity has a large range of variation due to the change of the sample volume. In order to reduce the difference between the volume of the reference cavity and the volume of the test cavity, To improve the accuracy, it can be equipped with an "expansion chamber" for "expanding" the volume of the reference chamber; when the sample volume is small, the standard reference chamber can be used; "Expand the cavity" to increase the volume of the reference cavity to adapt to the large-volume test cavity to achieve the purpose of improving accuracy.

7. Is it better to test positive pressure or negative pressure?

Positive pressure test means that the test pressure is higher than normal pressure, generally 0-1ba, and the instrument does not need a vacuum pump.

Negative pressure test means that the test pressure is lower than normal pressure. During the test process, a vacuum is required, and the instrument needs to be equipped with a vacuum pump.

For the true density test, since the highest test pressure is only 1 bar, it is far from high pressure, so for helium, the most difficult to liquefy gas among all gases, its properties are the closest to ideal gases among all gases near normal temperature and pressure. , the difference in the degree of idealization under negative and positive pressure conditions is negligible compared with the error requirement.

All materials that can be tested under negative pressure can be tested under positive pressure; the reverse is not possible. For example, for the test of a liquid with certain volatile properties, under the condition of vacuum negative pressure, its volatilization will be intensified, which is not conducive to the accuracy of the test; while under positive pressure, its volatilization will be suppressed, which is conducive to the accuracy of the test; in addition, for example For samples with a certain adsorption capacity, such as powders, porous materials, etc., when tested under vacuum negative pressure conditions, the influence of the sample’s adsorption of gas on the test results will be stronger than that under positive pressure conditions; therefore, for Negative pressure testing should be used with caution.

The real usefulness of negative pressure is not in the test, but in the sample processing process, which can improve the processing efficiency, shorten the processing time by about 30%, and shorten the processing time from 15 minutes to 10 minutes; the vacuum pump of the True Density Instrument of Bester is an optional accessory.

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported