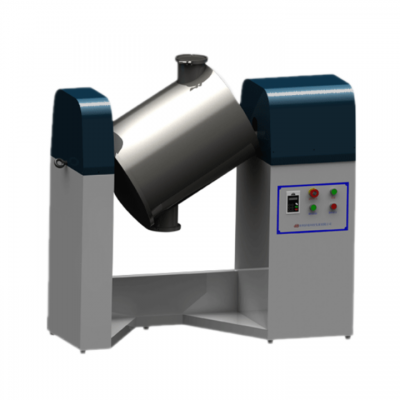

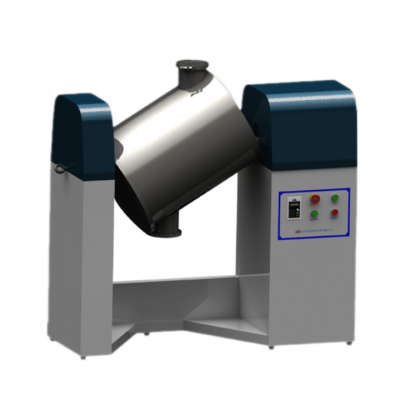

Industrial Horizontal Spiral Belt Electric Pneumatic Mixing Machine

Working principle

The horizontal spiral mixer is driven by the inner and outer diameter spiral installed on the mixing shaft to turn the material inside the barrel, so that the agitator can turn the material in the barrel to the maximum extent. When the mixer is working, the inner spiral drives the material near the shaft to do axial rotation, and the axial direction is pushed from inside to both sides, while the outer spiral drives the material near the barrel wall to do axial rotation, and the axial direction is pushed from both sides to inside, thus causing convection circulation and shear percolation of the material in the barrel, and completing the rapid and uniform mixing of the material in a short period of time.

Introduction

1. In the feasibility factor, the mixing effect of the horizontal spiral mixer is not affected by the size of the particles, density, and also has a good mixing effect on viscous materials.

2. The smooth mixing process reduces the damage to fragile materials, the addition of flying knife structure also plays a role in breaking.

3. Horizontal structure with low body height, easy to install.

4. Mixing structure, positive and negative rotating spiral installed in the same horizontal axis, forming a low power efficient mixing environment.

5. The horizontal spiral mixer is mainly used for the production of putty powder and can also be used as an entry level insulation mortar mixer.

Technical parameters

|

Model |

Motor power kw |

Total volume M3 |

Spindle speed r/min |

Mixing volume kg |

Dimensions |

Weight |

|

WLD-0.5 |

5.5 |

0.5 |

63 |

150~350 |

2372*812*1272 |

1050kg |

|

WLD-1.0 |

11 |

1.0 |

43 |

300~700 |

2700*1036*1574 |

1760Kg |

|

WLD-2.0 |

15 |

2.0 |

33 |

600~1400 |

3356*1236*1774 |

2500Kg |

|

WLD-3.0 |

18.5 |

3.0 |

33 |

900-2100 |

3356*1336*2024 |

3400Kg |

|

WLD-4.0 |

22 |

4.0 |

33 |

1200-2800 |

4210*1414*2108 |

4200Kg |

Function selection

|

Discharge method |

Manual, electric, pneumatic |

|

Spindle sealing method |

Packing seals, packing + gas seals, mechanical seals |

|

Agitator type |

Bi-directional continuous spiral belts, uni-directional continuous spiral belts, bi-directional disconnecting spiral belts, uni-directional disconnecting spiral belts |

|

Drive type |

Direct link, split (belt/chain) |

|

Mixer material |

Carbon steel, material contact stainless steel (SS304/SS316), all stainless steel (SS304/SS316), internally coated |

|

Main shaft |

Single-stage, multi-stage |

|

Barrel opening |

Standard flange opening, quick-opening feeding opening, dust collector opening, manual feeding opening, side cleaning door |

|

Discharge valve |

Butterfly, Ball, Plummer, Flap valves |

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported