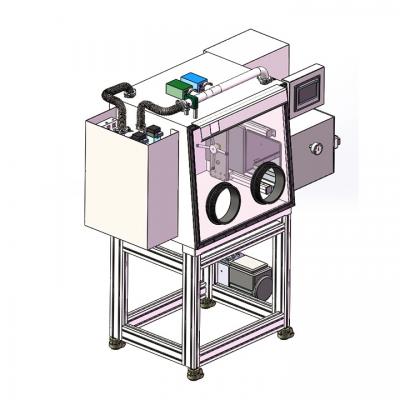

Benchtop Frictionless Spindle Electric Rockwell Hardness Tester

Product features:

1. The motor controls the loading, holding and unloading of the test force, and the holding time can be set;

2. The body of the machine uses high-quality cast iron casting molding, with automotive paint treatment process, the appearance of rounded and beautiful;

3. The dial reads the hardness value directly, and can be equipped with other Rockwell scales, such as HRD, HRF and other hardness scales;

4. Adopt frictionless spindle, high precision of test force;

5. Through the motor to control the test force loading, holding load, unloading, eliminating the manual Rockwell hardness tester human error;

6. Accuracy in accordance with GB/T230.2, ISO6508-2 and the U.S. ASTM E18 standards.

Scope of application:

1. Rockwell hardness of ferrous metals, non-ferrous metals, non-metallic materials;

2. Measurement of Rockwell hardness of quenched and tempered and other heat-treated materials, such as cemented carbide, carburized steel, quenched steel, surface quenched steel, hard cast steel, aluminum alloy, copper alloy, malleable castings, soft steel, tempered steel, annealed steel, bearings and other materials.

Technical parameters:

|

Model |

200HRD-150 |

|

Measurement range |

20-95HRA, |

|

Test force |

588.4、980.7、1471N |

|

The allowable upper limit height of the specimen |

200mm |

|

The distance from the middle of the press head to the machine wall |

165mm |

|

Hardness resolution |

0.5HR |

|

Power supply |

AC 220V,50Hz |

|

External dimensions |

510*290*730mm |

|

Weight |

80kg |

Attachment configuration:

|

Large flat working table |

1pc |

Small flat working table |

1pc |

|

V-shape working table |

1pc |

Diamond conical indenter |

1pc |

|

φ1.588 steel ball indenter |

1pc |

Standard Rockwell hardness block |

5pcs |

The above is the standard configuration, the actual product shall prevail in kind!

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported