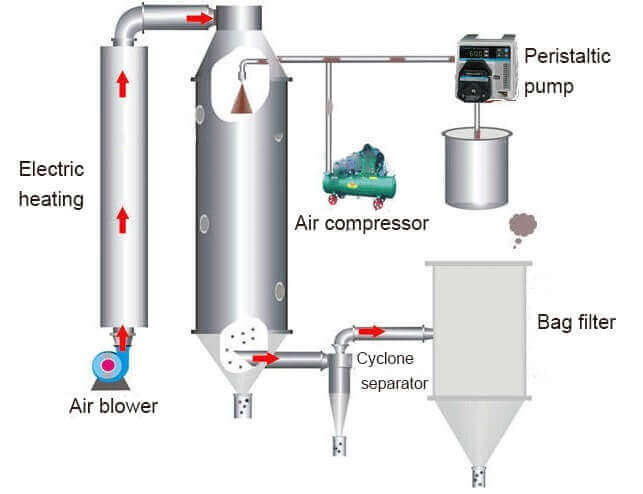

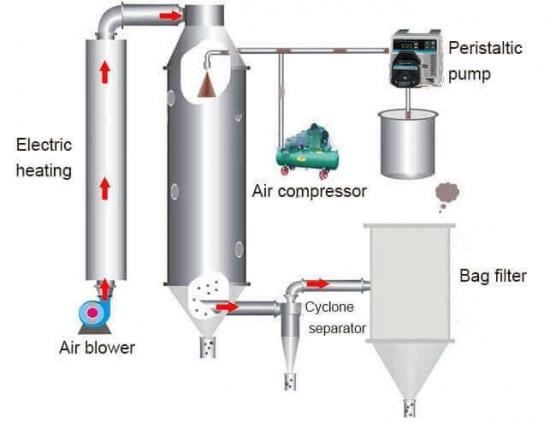

Powder Spray Dryer Equipment

Isolation equipment adopt high speed centrifuge spray drying technology, which is especially suitable for drying the heat sensitive materials, after drying, there's no need for smashing and sorting, so as to reduce the operation procedures and save your time.

Parameter

|

Max capacity

|

1500-3000ml/h

|

|

Temperature range of Inlet air

|

30℃-300℃

|

|

Temperature range of outlet air

|

30℃ -140℃

|

|

Precision of temperature

|

± 1℃

|

|

Dryer time

|

1.0-1.5 S

|

|

Speed of squirmy pump

|

30-3000ml/h

|

|

Consume of dryer air

|

0-330m3 /h, max pressure: 686Pa

|

|

Consume of spray air

|

0-4.2m3 /h, spray pressure: 2-5bar

|

|

Spray system

|

2 liquid nozzles with standard 0.7mm jet

options of 0.5/1.0/1.5/2.0/2.5mm

|

|

Spray direction

|

downwards co-current

|

|

Power

|

4.5KW 108V-240V

|

|

Dimensions

|

800*780*1450 ( mm ) L*W*H

|

Spray dryer can be used in a wide range where the production of a free-flowing powder sample is required. This technique has processed materials in the following areas successfully:

Beverages, Flavours and Colouring, Milk and Egg Products, Plant and Vegetable Extracts, Pharmaceuticals, Heat sensitive Materials, Plastics, Polymers and Resins, Perfumes, Ceramics and Advanced Materials, Soaps and Detergents, Blood, dyestuffs, Food Stuffs, Adhesives, Oxides, Textiles, Bones, Teeth and Tooth Amalgan and many others.

Most solutions and supernsions can be spray dried providing that the resulting product has the characteristics of material.

It is popular in fields of Food, biology, material, pharmacy, university, and R&D institute, etc. especially for processing temperature-sensitive material , for e.g., powder, because material only touch air for a brief moment so that heat couldn't destroy the component of material.

Air through filtering and heating, enter the hot air distributor which is at the top of spray dryer, hot air spiraling evenly into the drying chamber. Liquid through the high-speed centrifugal automizer which is at the top of drying chamber, (rotating) centrifugal spray into tiny fog droplet, then contact with the hot air flow, drying finish product in a very short time and whereabouts. Finished product output continuously between the drying tower bottom and cyclone separator, exhaust through dust catcher emptying by induced draft fan.

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported