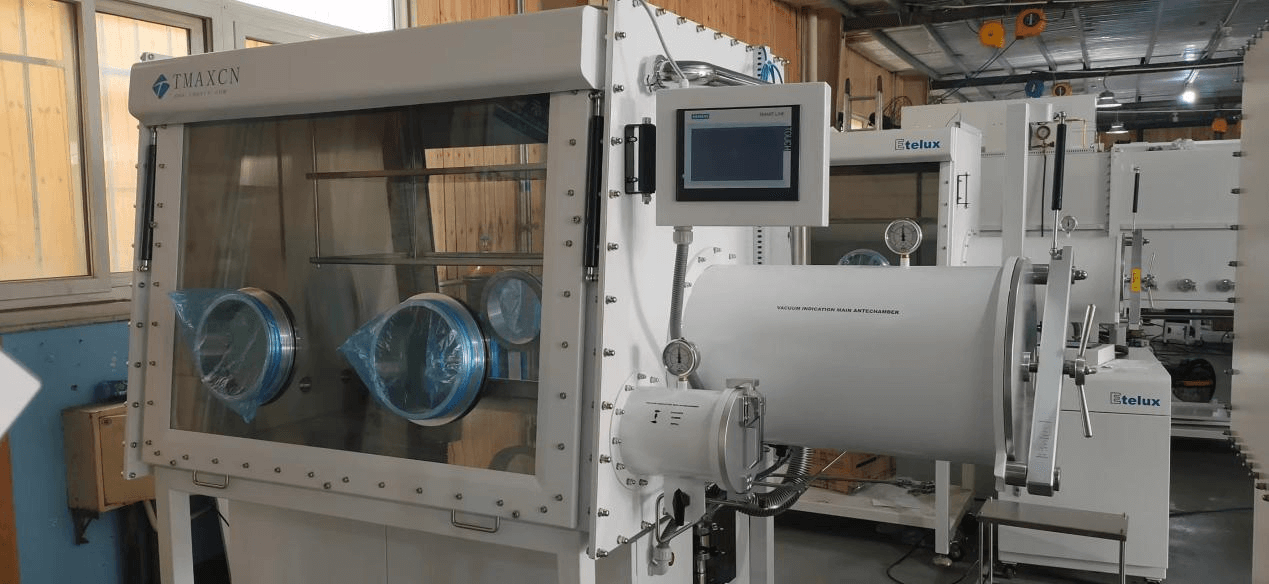

Lab Double Side Double Station Vacuum Glove Box with Water Analyzer

Technical solutions

1. Acceptance criteria

Under standard conditions, that is, constant temperature of 20-25 ℃, relative humidity of 65%, and inert gas source of 99.999%, the circulating water and oxygen indexes of the empty box are all less than 1ppm.

English panel, English operation screen.

2. The main technical indicators and configuration

1. Box

1.1. Size: 1220mm (length) × 900mm (height) × 1000mm (width) double-sided operation.

1.2. Material: All stainless steel structure (Type 304), thickness 3mm.

1.3. Filter: Pore size 0.3 microns

1.4. Butyl rubber gloves: imported from the United States, thickness 0.4mm, glove mouth 8 inches, hard aluminum alloy glove mouth (after anti-corrosion treatment, anodized aluminum), diameter 220mm.

1.5. Window: Operation surface with inclined design, removable 8mm safety tempered glass front window, wear-resistant, anti-corrosion, good light transmission, the sealing ring adopts 3/8 inch thick OMEGA sealing ring

1.6. It can maintain a certain positive and negative pressure during use (-10mbar-10mbar)

1.7. The box is equipped with anti-reflection lighting energy-saving lamps, and the light is soft.

1.8. There is a display board and 2 layers of adjustable shelves in the box

1.9. There is a multi-hole power terminal board in the box, and the socket is used for ***

1.10. The cabinet can be set with 3 standard KF-40 ports.

1.11. Leakage rate: ≤0.001vol%/h.

1.12. Steel structure bracket, height 950 mm including casters, installed with swivel casters.

2. Transition cabin

2.1. Shape: Cylindrical (304 stainless steel), connected to the glove box, with shaft lock type large transition hatch, easy to operate.

2.2. Size: diameter 360mm, length 600mm large transition cabin, piston door, sliding tray in the transition cabin, polished, another small transition cabin in the box, specifications: diameter 150mm, length 300mm, manual valve control air extraction and air supply .

2.3. Tray: stainless steel, free to move and extend (large transition cabin configuration)

2.4. Vacuum degree ≤ 1bar (both large and small right transition cabins require vacuum belt display)

3. Control system

3.1. Mode: including self-diagnosis, self-starting characteristics after power failure, with pressure control and self-adaptive functions. LCD display is used for automatic control, cycle control, password protection, and vacuum chamber control. The unit control adopts Siemens PLC touch screen.

3.2. Pressure control: control the pressure of the box and transition cabin at a certain set value.

a) The user can arbitrarily set the working pressure range between +12.5 and -12.5 mbar, and the PLC will automatically control the box pressure within the set range. The default value for the working pressure range is -1 to +3 mbar.

b) When the box pressure is greater than 12 mbar, the PLC will automatically open the safety valve to release the pressure to protect the gloves, equipment and materials in the box.

c) Use the foot switch to fine-tune the tank pressure.

3.3. Foot pedal: can control the pressure of the glove box, easy to operate.

4. Circulation system (including purification and regeneration system)

4.1. German BASF, American UOP purification material, German Baode valve. The host system integrates modular design, fully automatic electronically controlled gas circuit solenoid valve group, PLC control, circuit, circulating pump, purification, and display integrates an independent purifier to form a compact and simple system.

4.2. Control: Water and oxygen are controlled at less than 1PPm

4.3. Adjustment device: through PLC touch adjustment (heating, evacuation, purification, regeneration), the whole process does not require human monitoring except for 2.5 hours of ventilation.

4.4. Working gas: He.N2/or Ar gas (gas circulation)

4.5. Circulation fan: 0-100m³ high-speed variable frequency fan, microprocessor controlled, stainless steel device that has been pressure tested.

4.6. Purification column: single purification column, imported purification material German BASF deaerator material 10kg, UOP high-efficiency water absorbing material 10kg, extremely high life expectancy, to ensure long-lasting purification ability of the product during use. The water removal capacity is 2.2㎏ and the oxygen absorption capacity is 63L.

4.7. Purge valve: fully automatic electric valve.

4.8. Filter: High-efficiency filter with HEPA-compliant 0.3 micron pore size filter.

4.9. Regeneration: It is used to re-use and activate the purification system; regeneration requires a mixture of helium/H2, nitrogen/H2 or argon/H2, of which H2 accounts for 10%.

The regeneration gas is fed into the purification column by an advanced flowmeter.

5. Display system.

Germany SIEMENS, the unit control adopts Siemens PLC touch screen. Chinese and English bilingual can be switched.

6. Vacuum system

Increase the vacuum pump start and stop time control. The vacuum pump is a British Edwards vacuum pump, model RV12, with a flow rate of 12m3/h and an ultimate vacuum of 2x10-3 mbar. The transition cabin can be evacuated separately, and can be controlled independently at any time. (imported from abroad)

7. Automatic cleaning of the box

Automatic gas control electroplating board; the gas in the box is automatically cleaned by the user to set the cleaning time, and then touch the start button on the touch screen, the system will start cleaning the box, and it will automatically stop when the set time is reached. Automatic box cleaning function. Gas environment replacement of different natures and automatic cleaning of water and oxygen by misoperation. The automatic cleaning valve of the box and the integration of the box pipeline are firmly connected by KF25 steel wire plastic pipe, and the external interface is KF25 pagoda joint.

8. Organic solvent adsorption system

In order to prevent the influence of organic solvents on the purification column, a solvent column is connected in series to the glove box system, and the media are mainly high-quality and high-efficiency activated carbon and activated alumina to prevent the formation of hydrofluoric acid. The filling capacity of the organic solvent adsorption system is 7KG. There are KF40 ports on the top and bottom of the column, which is convenient for refueling. Users can refuel by themselves. In order to prevent the formation of hydrofluoric acid, half of the solvent column tank is activated alumina.

3. Main technical indicators and configuration

1. Water analyzer, (imported from abroad) Brand material: British MICHELL/ (determined according to the customer's use environment)

Non-domestic or domestic assembly, third-party data to ensure credibility.

1) Measuring range: 0-1000ppm

2) Accuracy: ±1% ppm

3) Display: The output of the analyzer is connected to the PLC, the detection value is displayed on the touch screen, and the alarm value can be set.

4) Control: The gas circulation system can be controlled according to the user's setting to realize the circulation drop.

5) Environment: -10℃-50℃

2. Oxygen analyzer, (imported from abroad) Brand material: American AVCRAY (determined according to the customer's use environment)

Non-domestic or domestic assembly, third-party data to ensure credibility.

1) The measurement range can be set: 0-1000, ppm

2) Environment: -10℃-50℃

3) Accuracy: ±1% ppm

4) Installation position: The oxygen sensor is installed on the box. No matter whether the gas is circulating or not, the oxygen sensor continuously detects the atmosphere in the box and displays the oxygen content in the glove box.

5) Sensor: Electrochemical material battery, which has the advantages of accurate zero point, small drift, avoiding the easy corrosion of other battery materials; low replacement cost (only oxygen battery is replaced).

6) Display: The output of the analyzer is connected to the PLC, the detection value is displayed on the touch screen, and the alarm value can be set.

7) Control: The user can choose the automatic circulation function to maintain the oxygen content in the glove box within the user's specified range.

4. The main configuration

|

No. |

Configure |

Unit |

Qty |

Manufacturer/Brand |

Remark |

|

1 |

Box |

Set |

1 |

TMAX |

304 stainless steel thickness 3mm |

|

2 |

Transition cabin |

Set |

1 |

TMAX |

304 stainless steel |

|

3 |

Control System |

Set |

1 |

Germany SIEMENS Omron electronic devices, etc. |

Import assembly |

|

4 |

Circulation system (including purification and regeneration system) |

Set |

1 |

German BASF, American UOP purification material, German Baode valve |

Import assembly |

|

5 |

Display system |

Set |

1 |

SIEMENS Germany |

Import |

|

6 |

Gloves |

Pair |

2 |

U.S. |

Import |

|

7 |

Pipe interface |

Set |

1 |

French Lacoli |

Import |

|

8 |

Pressure gauge |

Set |

1 |

Germany WIka |

Import |

|

9 |

PLC Water Analyzer |

Set |

1 |

Michell UK |

Import |

|

10 |

PLC oxygen analyzer |

Set |

1 |

American AVCRAY |

Import |

|

11 |

Vacuum pump |

Set |

1 |

RV12 |

Import |

|

12 |

Solvent column |

Set |

1 |

Activated carbon + activated alumina |

Domestic |

|

13 |

Automatic cleaning |

Set |

1 |

North Sichuan |

Give away |

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported